The global chemical industry stands at a pivotal crossroads, balancing the twin imperatives of cost optimization and process innovation. With fluctuating raw material prices, energy volatility, and tightening environmental regulations, chemical manufacturers can no longer rely solely on scale or legacy efficiency models to stay competitive. The future belongs to organizations that can continuously benchmark, innovate, and transform operations through data-driven intelligence.

Strategic benchmarking has become an essential enabler of this transformation. It allows chemical producers to evaluate their operational efficiency, R&D productivity, digital readiness, and sustainability performance against global peers. More importantly, it translates those insights into actionable strategies that enhance both process innovation and cost competitiveness.

Nexdigm’s Chemical Industry Strategic Benchmarking Services are designed to help enterprises navigate this complex environment with clarity and precision. By combining competitive intelligence, process benchmarking, and cost analysis, Nexdigm empowers chemical companies to identify performance gaps, optimize operations, and achieve sustainable profitability in an increasingly innovation-led industry.

Why Strategic Benchmarking Matters for the Chemical Industry

The chemical industry operates in a high-stakes environment where margin pressure, sustainability compliance, and technological evolution demand constant reinvention. Strategic benchmarking provides the clarity needed to navigate these challenges by revealing how an organization’s processes, costs, and innovation capabilities compare with global leaders.

- Enhancing Operational Efficiency: Benchmarking helps chemical manufacturers evaluate plant utilization rates, yield optimization, and overall equipment effectiveness (OEE) across facilities and geographies. This enables companies to pinpoint inefficiencies, reduce energy waste, and streamline production workflows, driving measurable gains in output and cost control.

- Accelerating Process Innovation: With product life cycles shortening and competition intensifying, innovation speed determines market success. Benchmarking R&D productivity, technology adoption, and process improvement initiatives allows companies to identify innovation bottlenecks and adopt proven best practices that accelerate time-to-market.

- Strengthening Cost Competitiveness: In a sector where raw material and utility costs can fluctuate dramatically, benchmarking cost structures across peers helps uncover hidden savings opportunities. Companies gain insight into procurement efficiency, energy intensity, and logistics optimization, enabling smarter resource allocation and higher profitability.

- Building Digital and Automation Maturity: As Industry 4.0 reshapes manufacturing, chemical players must evaluate their digital readiness. Benchmarking automation levels, predictive maintenance practices, and advanced analytics adoption helps organizations identify gaps in digital capability and implement technologies that enhance precision, safety, and reliability.

- Aligning Sustainability and Compliance Goals: Benchmarking environmental performance indicators such as carbon intensity, water usage, and waste management efficiency allows manufacturers to strengthen ESG alignment. This supports both regulatory compliance and customer trust in an era of growing environmental accountability.

In essence, strategic benchmarking enables chemical companies to convert data into a performance blueprint, achieving the delicate balance between innovation leadership and cost discipline.

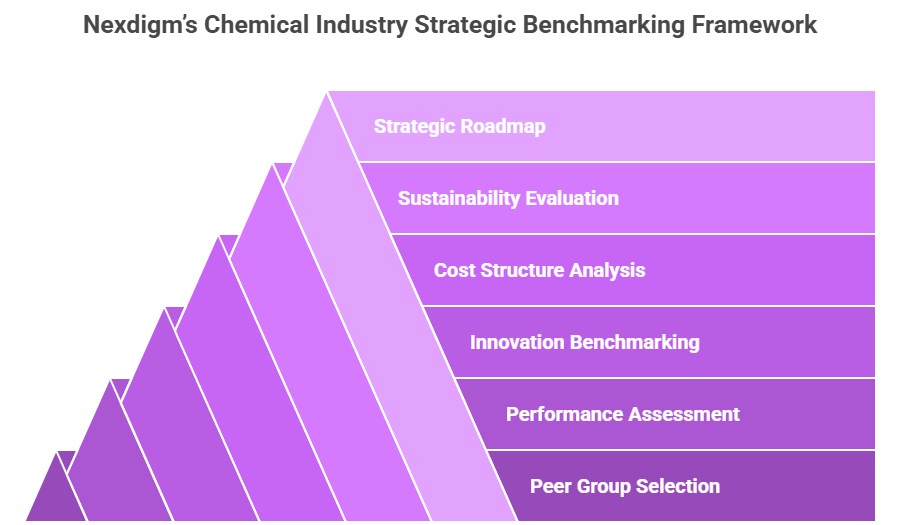

Nexdigm’s Chemical Industry Strategic Benchmarking Framework

Nexdigm’s Chemical Industry Strategic Benchmarking Framework is designed to help manufacturers turn operational complexity into measurable improvement. Built around a combination of data-driven analysis, process intelligence, and innovation assessment, the framework offers a comprehensive approach to benchmarking performance across production, cost, R&D, and sustainability dimensions.

- Peer Group Selection and Contextual Benchmarking: We begin by identifying relevant peer clusters matched by process type (batch, continuous, or specialty), production scale, and market segment. This ensures that every comparison is contextually accurate and reflects the organization’s true competitive landscape.

- Performance and Process Efficiency Assessment: Nexdigm benchmarks key operational and financial indicators such as plant utilization, yield ratios, cycle times, energy consumption, and throughput efficiency. The analysis highlights performance gaps across facilities and identifies best practices that can be replicated to improve productivity and reduce downtime.

- R&D and Innovation Benchmarking: Our framework assesses innovation efficiency, technology adoption rate, and R&D return on investment, mapping how top performers integrate automation, analytics, and digital twins into their innovation processes. This enables companies to accelerate development pipelines and shorten time-to-commercialization for new products.

- Cost Structure and Value Chain Analysis: We conduct detailed benchmarking of cost competitiveness, evaluating spending across raw materials, utilities, labor, logistics, and maintenance. By identifying cost drivers and efficiency gaps, Nexdigm helps organizations optimize resource allocation and improve EBITDA margins.

- Sustainability and Digital Maturity Evaluation: In an era of rising ESG expectations, our benchmarking framework also measures carbon footprint, circular economy practices, and digital readiness. This allows chemical manufacturers to align with sustainability mandates while leveraging automation and data analytics to enhance long-term resilience.

- Strategic Roadmap and Implementation Support: The final stage translates benchmarking outcomes into a strategic improvement roadmap. Nexdigm partners with leadership teams to prioritize investments, redesign processes, and establish a continuous benchmarking cycle.

Nexdigm’s Chemical Industry Strategic Benchmarking Services empower organizations to unlock their full operational potential. By integrating competitive intelligence, process benchmarking, and innovation analytics, we help chemical enterprises streamline production, accelerate R&D efficiency, and enhance sustainability performance.

To take the next step, simply visit our Request a Consultation page and share your requirements with us.

Harsh Mittal

+91-8422857704