The chemical industry operates at the intersection of complex processes, precision engineering, and constant innovation. As global demand grows and environmental standards tighten, manufacturers are turning toward digitization and automation to stay competitive. Technologies such as advanced process control (APC), IoT-based monitoring, predictive maintenance, and AI-driven analytics are transforming how plants operate, improving yield, quality, and safety.

Yet, despite these advancements, a critical gap persists: many companies lack clear visibility into how their technologies perform. Plants often run on a mix of legacy and modern systems, each producing valuable data but rarely connected or benchmarked for true efficiency. This results in operational blind spots, inconsistent throughput, and missed optimization opportunities.

To remain competitive in a resource-intensive industry, chemical manufacturers must not only adopt new technology but measure its impact systematically. That’s where benchmarking becomes a strategic differentiator.

The Challenge: Technology Silos and Unmeasured Process Efficiency

In a sector driven by precision, safety, and cost optimization, the chemical industry faces a fundamental challenge of the coexistence of advanced and outdated technologies within the same value chain. While automation, analytics, and digital tools are being rapidly deployed, their performance often remains unmeasured, isolated, or underutilized.

Below are the key barriers that limit operational efficiency and digital transformation across chemical plants:

- Fragmented Automation Systems: Many plants run on disparate Distributed Control Systems (DCS), PLCs, and legacy SCADA architectures that are not fully integrated. This creates blind spots in monitoring, makes data aggregation difficult, and prevents unified performance measurement.

- Inconsistent Process Data Visibility: Large volumes of process and asset data are generated daily, yet without standardized analytics frameworks, most of it remains underused. The absence of centralized dashboards hinders optimization and decision-making.

- Underutilized Digital Investments: Companies frequently invest in new automation or digital tools without benchmarking ROI. This leads to partial adoption, where technologies exist but fail to deliver measurable improvement.

- Energy and Resource Inefficiencies: With energy often accounting for 30–40% of total production costs, inefficiencies in heat recovery, utilities, and emissions monitoring can significantly reduce profitability. Benchmarking such parameters is essential for resource optimization.

- Rising Regulatory and ESG Pressures: As global sustainability frameworks tighten, chemical producers face increasing pressure to track emissions, waste, and safety performance digitally. Yet, fragmented systems make compliance monitoring both costly and reactive.

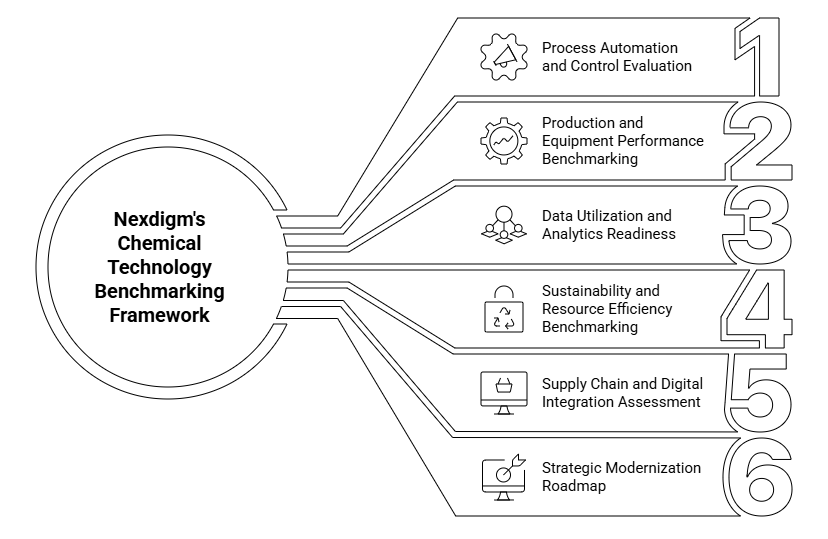

Nexdigm’s Chemical Industry Technology Benchmarking Framework

Efficiency in chemical manufacturing is about measuring how effectively they perform, integrate, and scale. Nexdigm’s Chemical Industry Technology Benchmarking Framework provides a structured, data-backed approach to assess the digital, automation, and operational maturity of chemical plants.

The framework brings together competitive intelligence, performance analytics, and process benchmarking to help manufacturers understand where they stand today, identify improvement areas, and design actionable roadmaps for measurable efficiency gains.

Core Components of the Framework

- Process Automation and Control Evaluation: Nexdigm benchmarks Distributed Control Systems (DCS), PLCs, and SCADA infrastructure across parameters such as system uptime, automation depth, and interconnectivity, helping plants identify integration bottlenecks and automation potential.

- Production and Equipment Performance Benchmarking: Each production line is evaluated using OEE (Overall Equipment Effectiveness) metrics, including yield, batch cycle times, downtime analysis, and energy consumption, compared against peer facilities to uncover underperforming assets.

- Data Utilization and Analytics Readiness: The framework measures how effectively plants use IoT-enabled sensors, real-time dashboards, and predictive analytics to transform process data into actionable insights for quality, safety, and predictive maintenance.

- Sustainability and Resource Efficiency Benchmarking: Nexdigm benchmarks the implementation of emissions tracking systems, waste heat recovery, and water reuse technologies, aligning performance with sustainability standards like ISO 14001 and GRI.

- Supply Chain and Digital Integration Assessment: Beyond production, the framework evaluates ERP–plant integration, logistics visibility, and materials traceability to ensure seamless coordination between manufacturing and distribution.

- Strategic Modernization Roadmap: All findings culminate in a customized modernization roadmap that highlights technology priorities, estimated ROI, and measurable KPIs, enabling data-driven decision-making for capital allocation and performance optimization.

Through this framework, Nexdigm helps chemical manufacturers turn operational data into competitive insight. Thus, building smarter, safer, and more sustainable production ecosystems that deliver efficiency across every reaction, process, and plant.

To take the next step, simply visit our Request a Consultation page and share your requirements with us.

Harsh Mittal

+91-8422857704