The construction chemical industry is witnessing a rapid transformation, driven by the global push toward sustainable infrastructure, regulatory compliance, and product performance consistency. From concrete admixtures and waterproofing compounds to sealants and repair mortars, manufacturers are under increasing pressure to ensure every formulation meets stringent quality and sustainability standards all while maintaining production efficiency.

However, many enterprises struggle with inconsistent batch performance, high raw material wastage, and uneven compliance across facilities. These inefficiencies not only impact profitability but also expose firms to regulatory risks and reputational damage.

Operational Benchmarking offers a strategic solution, enabling construction chemical manufacturers to evaluate their production efficiency, energy utilization, and compliance maturity against global peers. By identifying performance gaps, standardizing best practices, and optimizing resource utilization, benchmarking transforms infrastructure formulation from a reactive function to a strategic performance driver.

In a market where precision, safety, and sustainability define success, operational benchmarking becomes the cornerstone of continuous improvement, compliance excellence, and cost competitiveness.

Nexdigm’s Construction Chemical Operational Benchmarking Framework

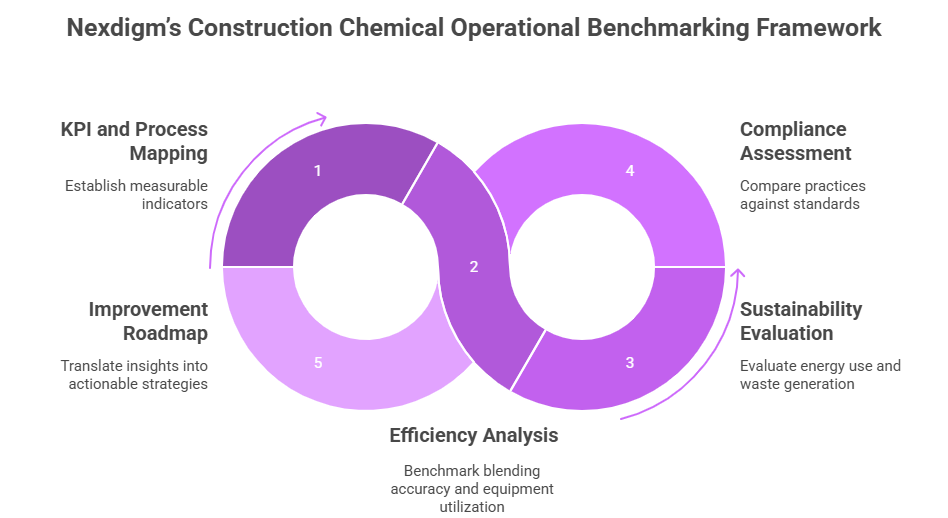

Nexdigm’s Construction Chemical Operational Benchmarking Framework enables manufacturers to achieve measurable efficiency, compliance, and sustainability across production and formulation processes. The framework blends process analytics, compliance benchmarking, and competitive intelligence to uncover hidden inefficiencies and align manufacturing practices with global best standards.

Core Components of the Framework

- KPI and Process Mapping: Establishes measurable indicators across raw material yield, batch cycle time, energy consumption, emissions, and product consistency.

- Formulation and Production Efficiency Analysis: Benchmarks blending accuracy, downtime, and equipment utilization to enhance throughput and reduce process variability.

- Energy and Waste Benchmarking: Evaluates energy use per batch, waste generation rates, and water recycling efficiency to improve sustainability.

- Regulatory and Quality Compliance Assessment: Compares operational practices against ISO, REACH, and environmental compliance standards, ensuring audit readiness and global market eligibility.

- Improvement Roadmap: Translates benchmarking insights into clear, actionable strategies from process redesign to technology upgradation and workforce training.

By implementing this framework, Nexdigm helps manufacturers transform formulation precision and compliance management into strategic differentiators, building resilient, efficient, and sustainable operations across the construction chemical value chain.

Strategic Benefits for Construction Chemical Manufacturers

Implementing Nexdigm’s Operational Benchmarking Framework empowers construction chemical manufacturers to enhance efficiency, strengthen compliance, and achieve sustainable growth. By aligning production and quality systems with global benchmarks, organizations can convert operational insights into tangible business outcomes.

Key Benefits

- Improved Production Efficiency: Identifies performance bottlenecks and optimizes batch cycles, material handling, and blending operations for higher throughput.

- Regulatory and Audit Readiness: Ensures consistent compliance with ISO, REACH, and environmental standards, reducing risk of non-conformance or recall.

- Sustainability and Cost Control: Benchmarks energy consumption, waste generation, and water usage, helping manufacturers lower their environmental footprint and production costs.

- Enhanced Product Consistency: Standardizes formulation and QC parameters across facilities, ensuring predictable product performance and reduced rework.

- Data-Driven Decision-Making: Provides leadership with measurable insights for continuous process improvement, technology adoption, and capacity expansion.

Through operational benchmarking, construction chemical manufacturers can move from reactive compliance to proactive excellence, delivering reliable, efficient, and sustainable formulations that meet the evolving demands of global infrastructure markets.

To take the next step, simply visit our Request a Consultation page and share your requirements with us.

Harsh Mittal

+91-8422857704