Quality in manufacturing is about consistently exceeding customer expectations while staying compliant with global regulations. In an era of rapid product cycles, complex supply chains, and rising customer demands, manufacturers cannot afford to treat quality as a static goal. Instead, it must be nurtured through a process of continuous improvement.

Yet, continuous improvement cannot succeed in isolation. Manufacturers need clear visibility into how their operations and quality outcomes measure up against peers and industry leaders. This is where performance benchmarking plays a vital role. By aligning continuous improvement initiatives with benchmarking insights, organizations can identify gaps, set realistic goals, and create a structured path toward sustained quality excellence.

Continuous Improvement and Performance Benchmarking

Continuous improvement in manufacturing is built on principles such as Kaizen, Lean, and Six Sigma, all of which emphasize small, consistent changes that lead to long-term excellence. But for these initiatives to truly deliver results, they must be backed by clear, comparative benchmarks. Without knowing how performance stacks up against peers or industry leaders, manufacturers risk setting goals that are either too ambitious or too conservative.

Performance benchmarking in manufacturing acts as the compass for continuous improvement by:

- Highlighting Gaps – Identifying where current processes fall short compared to best-in-class practices.

- Setting Realistic Targets – Defining improvement goals grounded in external market realities, not just internal assumptions.

- Driving Accountability – Ensuring teams measure progress against transparent, industry-aligned standards.

- Sustaining Progress – Enabling organizations to track whether quality gains are consistent over time or stagnating.

By linking continuous improvement efforts with robust benchmarking, manufacturers create a structured, data-driven pathway to quality excellence.

How Benchmarking Drives a Culture of Continuous Quality Improvement

Benchmarking shapes mindsets and behaviors within manufacturing organizations. By making performance gaps visible, it fosters a culture where continuous improvement is not optional but embedded into daily operations.

Key ways benchmarking drives this culture include:

- Promotes Proactive Problem-Solving – Instead of reacting to defects or customer complaints, benchmarking encourages teams to anticipate issues by comparing with industry standards.

- Encourages Cross-Functional Collaboration – Quality improvement becomes a shared responsibility across production, supply chain, and R&D when benchmarks highlight interdependencies.

- Creates Transparency and Accountability – Metrics aligned with peers ensure leaders and frontline teams alike know where they stand.

- Supports Innovation – By revealing where competitors excel, benchmarking inspires adoption of new processes, technologies, and quality practices.

- Builds Long-Term Resilience – Continuous benchmarking ensures that quality gains are not short-lived but evolve with changing market demands and compliance norms.

Ultimately, benchmarking embeds a continuous learning loop where manufacturers consistently refine processes, reduce defects, and enhance customer trust.

Nexdigm’s Manufacturing Competitive Intelligence Approach

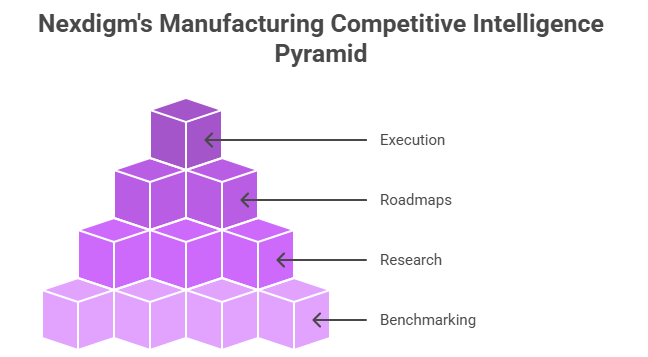

At Nexdigm, we help manufacturers go beyond data collection to achieve actionable intelligence that strengthens both efficiency and quality. Our Competitive Intelligence services integrate performance benchmarking with continuous improvement frameworks, ensuring organizations do not just measure performance but also act on it.

Our approach combines:

- Comprehensive Benchmarking Frameworks – Covering productivity, defect rates, cost efficiency, and sustainability standards across global leaders.

- Multi-Source Research – Leveraging primary studies, secondary data, and proprietary insights to deliver accurate, industry-specific benchmarks.

- Customized Roadmaps – Translating benchmarks into tailored strategies for reducing defects, cutting waste, and elevating product quality.

- Execution Support – Working with clients to implement improvement initiatives, track progress, and sustain long-term results.

By aligning continuous improvement practices with performance benchmarking, Nexdigm enables manufacturers to embed quality as a core differentiator, not just in production lines, but across the entire value chain.

To take the next step, simply visit our Request a Consultation page and share your requirements with us.

Harsh Mittal

+91 96549 82241