The FMCG manufacturing industry operates in a highly competitive environment where speed, consistency, and cost control define success. With evolving consumer demand, fluctuating raw material prices, and increasing sustainability expectations, manufacturers face constant pressure to achieve operational excellence.

Despite automation and advanced production technologies, many FMCG plants struggle with performance gaps in fill rate, line speed, and wastage control, three critical metrics that directly influence profitability and customer satisfaction. Identifying where these inefficiencies lie requires more than internal monitoring; it demands an objective, data-driven benchmarking approach.

Operational Benchmarking allows FMCG companies to compare their production, packaging, and supply chain performance with global best practices. By measuring plant efficiency, throughput, and resource utilization, organizations can uncover hidden improvement areas and develop actionable strategies for optimization. In a sector where every second and gram counts, benchmarking becomes the key to achieving faster production, minimal waste, and reliable supply continuity.

Understanding Operations Benchmarking in FMCG Manufacturing

Operational benchmarking in FMCG manufacturing is a structured approach to measuring production efficiency, process quality, and resource utilization against global best-in-class standards. It provides manufacturers with actionable insights into how their plants perform and where operational gaps exist, especially across fill rate, line speed, and wastage control.

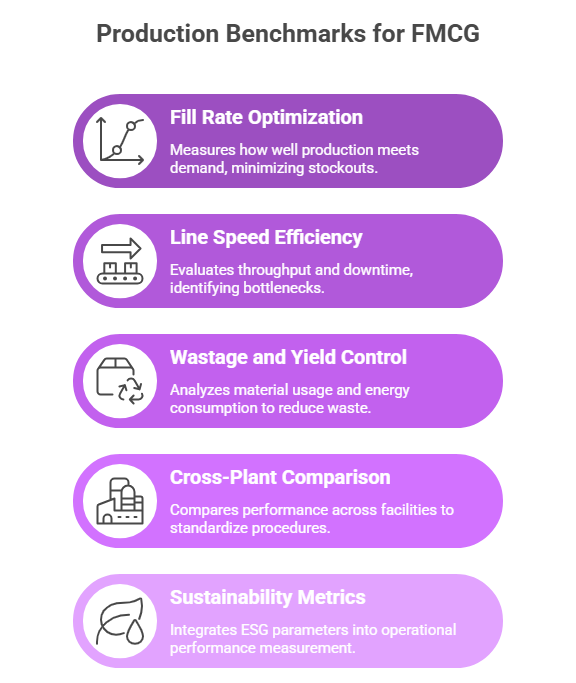

Key Areas of Focus

- Fill Rate Optimization: Benchmarks how effectively production output meets demand, ensuring minimal stockouts and improved order fulfillment accuracy.

- Line Speed Efficiency: Evaluates throughput and downtime across production lines, identifying bottlenecks that limit speed or increase changeover time.

- Wastage and Yield Control: Analyzes raw material usage, packaging losses, and energy consumption to minimize waste and enhance yield efficiency.

- Cross-Plant Comparison: Compares performance across facilities, helping organizations standardize operating procedures and share best practices.

- Sustainability Metrics: Integrates ESG parameters like water and energy efficiency into operational performance measurement.

By combining data analytics and process intelligence, operational benchmarking transforms FMCG operations into lean, agile, and quality-driven ecosystems, capable of delivering consistency and scalability across every production cycle.

Nexdigm’s FMCG Operational Benchmarking Framework

Nexdigm’s FMCG Operational Benchmarking Framework is designed to help manufacturers achieve data-backed operational excellence by evaluating and improving performance across key parameters such as fill rate, line speed, and wastage. The framework integrates process analytics, industry intelligence, and performance benchmarking to drive measurable efficiency improvements across production and supply chain functions.

Core Components of the Framework

- KPI Mapping and Data Standardization: Defines measurable KPIs for throughput, fill accuracy, changeover time, and yield to ensure consistent performance tracking across plants.

- Line Efficiency Assessment: Analyzes production flow, machine uptime, and maintenance cycles to identify capacity constraints and speed optimization opportunities.

- Wastage and Yield Benchmarking: Evaluates material losses, rework ratios, and energy consumption against global FMCG benchmarks to improve cost efficiency.

- Quality and Compliance Evaluation: Measures defect rates, packaging integrity, and adherence to safety and hygiene standards.

- Improvement Roadmap: Translates benchmarking insights into clear actions from process redesign and automation to training and technology upgrades.

Through this framework, Nexdigm enables FMCG manufacturers to convert operational data into strategic intelligence, ensuring faster production cycles, minimal waste, and higher product availability in the market.

To take the next step, simply visit our Request a Consultation page and share your requirements with us.

Harsh Mittal

+91-8422857704