Global manufacturing competitiveness today hinges on how efficiently organizations synchronize their supply chains and shopfloor operations. With rising input costs, geopolitical uncertainties, and fluctuating demand cycles, even the most advanced manufacturers are realizing that operational intelligence is the true differentiator.

Operational benchmarking allows enterprises to assess their performance across plants, suppliers, and logistics networks against global best practices. It identifies where efficiency gaps exist, how automation and workforce productivity compare across sites, and how supply chain agility can be strengthened.

For large-scale manufacturers and EPC (Engineering, Procurement, and Construction) firms, this approach ensures standardized performance measurement, enabling faster decisions, lower costs, and more resilient operations. In today’s interconnected manufacturing landscape, global benchmarking acts as a compass guiding companies toward measurable competitiveness, improved throughput, and sustainable efficiency.

Nexdigm’s Global Manufacturing Operational Benchmarking Framework

Nexdigm’s Global Manufacturing Operational Benchmarking Framework is built to help enterprises identify, quantify, and close performance gaps across multi-location operations. By integrating supply chain intelligence, shopfloor analytics, and cross-country performance data, the framework provides a unified lens for global efficiency measurement and improvement.

Key Components of the Framework

- KPI and Process Mapping: Establishes a consistent set of metrics across plants and regions, covering areas such as equipment utilization, production yield, procurement efficiency, and logistics performance.

- Cross-Plant and Supply Chain Comparison: Benchmarks facility performance, supplier reliability, and inventory cycles to identify regional best practices and global bottlenecks.

- Automation and Technology Readiness: Evaluates Industry 4.0 adoption, digital workflow integration, and automation ROI to align operational maturity across sites.

- Operational Gap Analysis: Highlights deviations in energy use, throughput, and lead time performance, providing quantifiable improvement potential.

- Strategic Action Planning: Translates insights into actionable roadmaps focused on cost reduction, productivity gains, and supply chain resilience.

By combining deep industry expertise with competitive intelligence, Nexdigm’s framework transforms global operational data into a strategic performance management system, helping manufacturers achieve standardization, scalability, and sustainable efficiency.

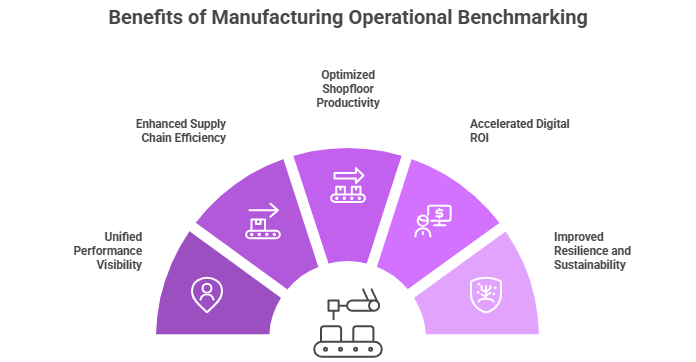

Strategic Benefits for Global Manufacturing Firms

Nexdigm’s Global Manufacturing Operational Benchmarking approach enables organizations to transform fragmented data into actionable competitive intelligence. By connecting supply chain and shopfloor performance insights, manufacturers can drive measurable improvements across cost, quality, and agility.

Key Strategic Benefits

- Unified Global Performance Visibility: Standardizes KPIs across regions, plants, and suppliers, ensuring consistent measurement and easier decision-making.

- Enhanced Supply Chain Efficiency: Identifies lead time bottlenecks, logistics inefficiencies, and supplier performance gaps to improve responsiveness and cost-effectiveness.

- Optimized Shopfloor Productivity: Pinpoints utilization, energy, and throughput inefficiencies, helping plants achieve best-in-class performance.

- Accelerated Digital and Automation ROI: Aligns technology adoption with tangible operational outcomes through benchmark-led digital transformation.

- Improved Resilience and Sustainability: Enables data-backed planning for risk mitigation, energy optimization, and ESG-aligned manufacturing.

Nexdigm’s benchmarking studies empower global manufacturers to continuously recalibrate performance, enabling a culture of continuous improvement, competitiveness, and operational excellence.

To take the next step, simply visit our Request a Consultation page and share your requirements with us.

Harsh Mittal

+91-8422857704