The rise of smart factories marks a turning point in global manufacturing, where data, automation, and digital collaboration are transforming production into an intelligent ecosystem. Yet, technology adoption alone does not define leadership in this new industrial era. The real differentiator lies in how manufacturers translate digital capability into product innovation, balancing performance, cost, and sustainability to meet evolving market expectations.

Across industries, global benchmarks in innovation, productivity, and design efficiency are setting new standards for what it means to be “smart.” However, many manufacturers still operate with limited visibility into how leading factories innovate at the product level.

This is where Nexdigm’s Global Manufacturing Benchmarking Intelligence becomes critical. It helps organizations evaluate their innovation readiness, identify global performance gaps, and create a data-backed product innovation strategy that aligns technology adoption with measurable business outcomes.

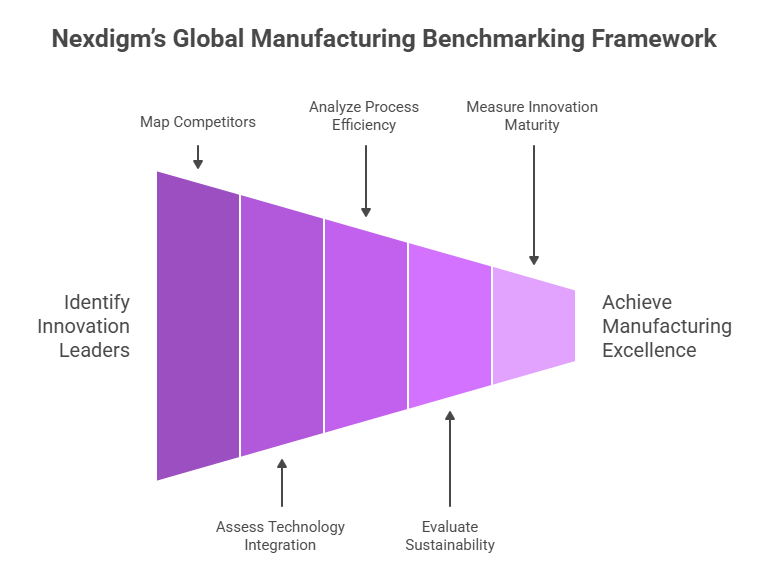

Nexdigm’s Global Manufacturing Benchmarking Framework

Nexdigm’s Global Manufacturing Benchmarking Framework is designed to help organizations convert benchmarking insights into innovation roadmaps that strengthen product competitiveness within smart factory ecosystems. The framework integrates operational intelligence, product engineering analysis, and digital maturity benchmarking to identify how manufacturers can transform technology investments into sustainable product leadership.

- Global Peer and Market Mapping: The process begins by identifying innovation leaders across industries and geographies. Nexdigm maps competitors based on automation depth, digital integration maturity, and product innovation velocity to establish a relevant peer baseline.

- Product and Technology Integration Benchmarking: Nexdigm assesses how global manufacturing leaders integrate advanced technologies such as IoT, robotics, additive manufacturing, and AI-driven quality systems within their product design and production cycles. This stage identifies how digital capabilities translate into tangible performance gains.

- Process Efficiency and Value Engineering Analysis: Through a combination of data analytics and engineering evaluation, the framework benchmarks material utilization, production energy intensity, yield optimization, and maintenance efficiency. The insights guide manufacturers toward targeted interventions that enhance product performance while minimizing lifecycle costs.

- Sustainability and Circularity Benchmarking: Nexdigm evaluates how leading factories embed eco-design, recyclability, and low-carbon material choices into their product development models. This helps clients align innovation with both environmental goals and emerging regulatory requirements.

- Innovation Maturity and R&D Effectiveness Assessment: The framework measures how effectively organizations translate R&D investments into commercial success. It benchmarks time-to-market, product adaptability, and innovation ROI, revealing which practices drive sustained product evolution within digitally mature manufacturing ecosystems.

Through this structured, intelligence-driven approach, Nexdigm enables manufacturers to benchmark not just operational performance but also innovation capability, empowering them to transform into globally competitive, technology-optimized smart factories.

Strategic Benefits of Nexdigm’s Global Manufacturing Benchmarking

Nexdigm’s benchmarking intelligence enables manufacturers to turn global insights into actionable innovation strategies. By evaluating product performance, digital maturity, and sustainability readiness, organizations can drive transformation that is measurable, targeted, and future-focused.

- Data-Driven Product Innovation: Benchmarking helps identify performance gaps and best practices across global leaders, guiding manufacturers to build innovation roadmaps that align design efficiency, automation priorities, and sustainability goals.

- Optimized Cost and Value Balance: By comparing cost-performance ratios and feature relevance, manufacturers uncover value engineering opportunities, refining materials, features, and production processes to improve margins without compromising quality.

- Accelerated Digital Transformation: Benchmarking top smart factories reveals how digital twins, predictive analytics, and automation directly influence product competitiveness, helping firms prioritize technology investments with clear ROI.

- Sustainability and Compliance Alignment: Through global ESG benchmarking, Nexdigm helps manufacturers integrate eco-design, recyclability, and emissions control into product strategies, ensuring regulatory compliance and green differentiation.

- Enhanced Market Positioning: Continuous benchmarking provides visibility into innovation trends and product evolution, enabling companies to differentiate through design, performance, and technological depth.

In essence, Nexdigm’s benchmarking transforms smart factories into innovation-driven ecosystems, where every product advancement contributes directly to competitiveness, profitability, and long-term growth.

To take the next step, simply visit our Request a Consultation page and share your requirements with us.

Harsh Mittal

+91-8422857704