The manufacturing landscape for Original Equipment Manufacturers (OEMs) is evolving faster than ever. Global competition, shorter product lifecycles, and rising expectations for sustainability and digital integration have made product performance and innovation the true benchmarks of success. In this environment, traditional measures such as output volume or cost efficiency no longer define leadership. What truly distinguishes high-performing OEMs is their ability to continuously benchmark and evolve their products in alignment with global innovation standards.

Modern OEMs must look beyond internal metrics and embrace benchmarking-driven manufacturing intelligence, a structured, data-backed approach that evaluates how industry leaders engineer quality, optimize costs, and integrate advanced technologies across their value chains. By doing so, organizations gain a clearer view of their competitive standing and a roadmap for building products that are smarter, more reliable, and market-ready.

In essence, benchmarking provides the foundation for a performance-first manufacturing strategy, where every design enhancement, process improvement, and technological upgrade is informed by real-world insights from the best-performing OEMs worldwide.

Why Benchmarking Matters for OEM Product Excellence

For OEMs, achieving consistent product excellence demands market intelligence, performance visibility, and innovation alignment. Benchmarking provides this clarity by helping manufacturers understand how their products perform relative to the best in class and where improvement opportunities exist across the value chain.

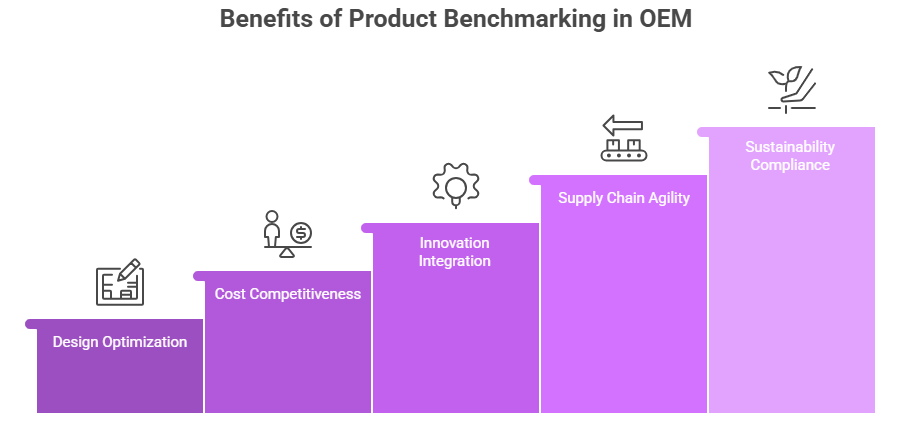

- Driving Design and Engineering Optimization: Benchmarking helps OEMs evaluate their product designs against global performance standards, uncovering inefficiencies in weight, material usage, and mechanical output. This enables manufacturers to fine-tune engineering specifications for better reliability, durability, and operational efficiency.

- Enhancing Cost Competitiveness: Through comparative analysis of pricing structures, material sourcing, and process costs, benchmarking identifies value engineering opportunities, allowing OEMs to balance cost with performance without compromising quality or brand reputation.

- Accelerating Innovation and Technology Integration: By studying how leading global OEMs adopt advanced technologies benchmarking reveals innovation gaps and directs R&D investments toward areas with the highest strategic impact.

- Improving Supply Chain and Production Agility: Benchmarking provides visibility into how market leaders manage sourcing, component standardization, and production flexibility, helping OEMs streamline their supply chains and reduce time-to-market.

- Strengthening Sustainability and Compliance: As sustainability becomes a global priority, benchmarking shows how top manufacturers integrate eco-design, emissions control, and circularity principles into product development, enabling OEMs to stay ahead of regulatory and ESG expectations.

Ultimately, benchmarking enables OEMs to move from incremental improvement to strategic competitiveness, transforming manufacturing data into actionable intelligence that drives higher-performing, market-ready products.

Nexdigm’s Benchmarking-Driven Manufacturing Framework for OEMs

Nexdigm’s Manufacturing Product Benchmarking Framework empowers OEMs to translate competitive intelligence into engineering excellence and product innovation. It integrates market analytics, performance benchmarking, and process optimization to help manufacturers redesign their product strategies for superior quality, efficiency, and sustainability.

- Peer and Product Mapping: The process begins with identifying relevant peers and competitors across domestic and global markets. Nexdigm evaluates product categories, technology maturity, and innovation velocity to establish a benchmarking baseline that reflects both market realities and future trends.

- Product and Performance Benchmarking: Each product is analyzed for technical performance, energy efficiency, durability, safety compliance, and cost-to-value ratio. This enables OEMs to pinpoint areas where design improvements or process refinements can deliver measurable competitive advantages.

- Technology and Material Innovation Assessment: Nexdigm examines how industry leaders integrate automation, robotics, advanced materials, and smart sensors into product development. By benchmarking technology adoption, OEMs can realign R&D efforts and accelerate their transition toward digital manufacturing.

- Value Engineering and Process Optimization: Benchmarking insights are converted into cost and process improvement roadmaps, helping OEMs reduce production waste, optimize assembly workflows, and enhance product reliability.

- Sustainability and Lifecycle Intelligence: The framework also benchmarks carbon footprint, material recyclability, and energy intensity, enabling OEMs to embed sustainability within product design and align with global ESG expectations.

By combining these insights, Nexdigm provides OEMs with a data-driven roadmap for innovation, guiding them to refine product design, accelerate digital transformation, and sustain competitive advantage in a rapidly evolving industrial ecosystem.

To take the next step, simply visit our Request a Consultation page and share your requirements with us.

Harsh Mittal

+91-8422857704