The manufacturing and construction industries are at a critical inflection point, where productivity, cost efficiency, and sustainability are redefining competitiveness. As global supply chains grow more complex and input costs fluctuate, enterprises can no longer rely solely on traditional process audits or internal KPIs. Instead, leading manufacturers and EPC (Engineering, Procurement, and Construction) firms are adopting Operational Benchmarking as a strategic tool to evaluate performance against global best practices and uncover new levers of excellence.

Operational benchmarking goes beyond measuring productivity; it creates a continuous improvement loop that connects process efficiency, resource utilization, and digital maturity. Whether in discrete manufacturing (automotive, electronics, machinery) or process industries (cement, steel, chemicals), benchmarking enables decision-makers to identify performance gaps, optimize throughput, and accelerate transformation initiatives.

At a time when lean manufacturing, ESG mandates, and automation are shaping industrial priorities, Operational Benchmarking has emerged as the backbone of competitive intelligence, allowing organizations to move from reactive to proactive performance management.

Understanding Operational Benchmarking in Manufacturing

Operational benchmarking in manufacturing is the process of systematically measuring an organization’s performance, processes, and practices against peers or industry leaders. It enables decision-makers to understand where their operations stand, identify performance gaps, and implement targeted improvements to boost productivity, quality, and profitability. Unlike traditional audits, operational benchmarking combines data-driven analysis, process diagnostics, and best-practice intelligence to drive sustainable transformation.

How It Applies Across Industry Types

- Discrete Manufacturing: Focuses on optimizing assembly lines, reducing cycle times, and improving material yield. Benchmarking parameters often include Overall Equipment Effectiveness (OEE), first-pass yield, machine utilization, and supply chain lead times.

- Process Industries: Centers around energy efficiency, throughput stability, and yield optimization. Benchmarking here measures energy consumption per unit output, downtime analysis, process control efficiency, and raw material conversion rates.

- Construction and Infrastructure: Emphasizes project execution efficiency, labor productivity, and resource utilization. Typical metrics benchmarked include project turnaround time, equipment idle time, safety performance, and procurement cycle efficiency.

Why It Matters

- Identifies hidden inefficiencies and bottlenecks in production or project delivery.

- Enables cost optimization by comparing internal KPIs with industry best-in-class metrics.

- Strengthens resilience by fostering continuous improvement and data-based decision-making.

- Provides a factual foundation for digital transformation, lean initiatives, and ESG compliance.

When executed effectively, operational benchmarking acts as a continuous improvement engine, transforming operational data into actionable intelligence that drives competitiveness and sustainable growth.

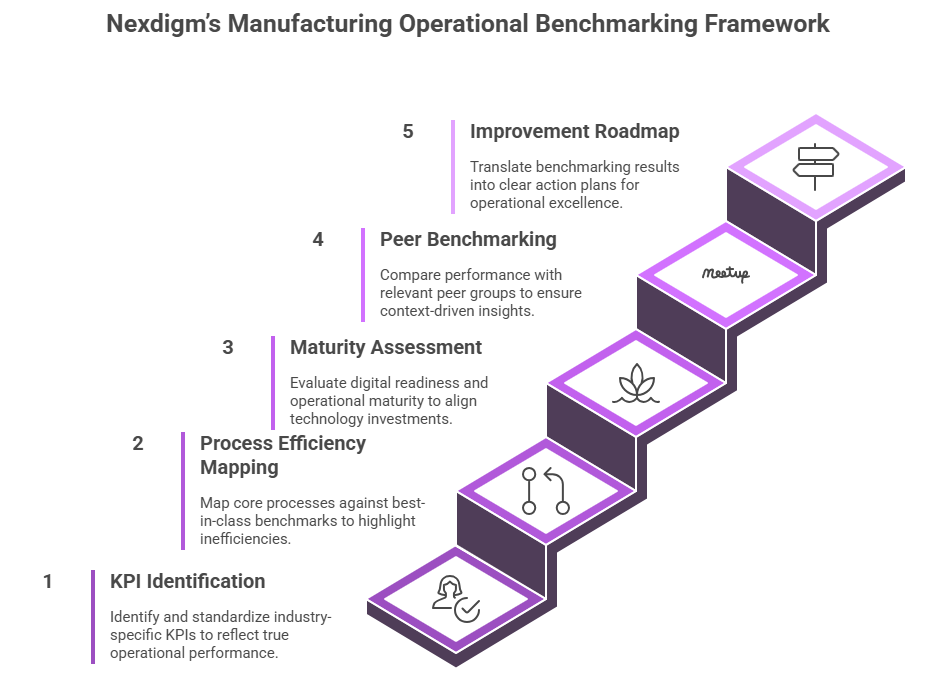

Nexdigm’s Manufacturing Operational Benchmarking Framework

Nexdigm’s Manufacturing Operational Benchmarking Framework is designed to help manufacturing and construction enterprises quantify performance, identify optimization levers, and embed continuous improvement across production and project ecosystems. Our approach integrates competitive intelligence, data analytics, and industry best practices to transform benchmarking into a strategic enabler of operational excellence.

Key Components of the Framework

- KPI Identification and Data Standardization: We begin by identifying industry-specific Key Performance Indicators (KPIs) that reflect true operational performance, covering productivity, quality, cost efficiency, and sustainability. Our benchmarking datasets ensure comparability across discrete and process industries by standardizing data definitions and measurement practices.

- Process Efficiency Mapping: Nexdigm maps core processes against best-in-class benchmarks. This analysis highlights performance deviations, resource inefficiencies, and opportunities for automation or redesign.

- Digital and Operational Maturity Assessment: We assess a client’s digital readiness and operational maturity by evaluating ERP, MES, IoT, and automation adoption. The goal is to align technology investments with performance improvement outcomes and industry 4.0 readiness.

- Peer Group and Best Practice Benchmarking: Leveraging Nexdigm’s extensive cross-sector database, we compare clients’ performance with relevant peer groups. This ensures insights are context-driven, not generic.

- Gap Analysis and Improvement Roadmap: Our consultants translate benchmarking results into clear action plans. These include cost-saving opportunities, process redesign recommendations, skill enhancement strategies, and sustainability measures.

At Nexdigm, we view benchmarking not as a one-time assessment but as a living intelligence system, continuously feeding insights that drive agility, resilience, and global competitiveness for manufacturing and construction enterprises.

To take the next step, simply visit our Request a Consultation page and share your requirements with us.

Harsh Mittal

+91-8422857704