Global manufacturing is at a turning point, shaped by Industry 4.0 adoption, digital supply chains, sustainability mandates, and rapidly evolving customer expectations. To stay competitive, manufacturers must move beyond incremental improvements and embrace data-driven operational excellence.

According to UNIDO and World Bank, the global manufacturing sector contributes nearly USD 16 trillion to world GDP, yet productivity gaps between top-quartile and average performers remain as wide as 30–35%. This disparity is often not due to technology access, but the lack of comparative insight into what defines world-class performance.

That’s where Strategic Benchmarking comes in. It provides a structured, analytical way for manufacturers to measure their operational, technological, and cost performance against industry leaders, uncover best practices, and set realistic improvement targets.

Why Strategic Benchmarking Matters in Manufacturing

Global manufacturers are under constant pressure to balance efficiency, cost optimization, and technological agility while navigating market volatility and evolving customer demands. Yet, many organizations struggle to quantify where they stand in comparison to global peers, making it difficult to prioritize the right improvement levers.

Strategic Benchmarking addresses this challenge by transforming performance evaluation into a structured, data-driven exercise. It allows manufacturers to compare operations, productivity, and innovation maturity against leading industry performers and identify the performance gaps that truly matter.

Why it matters:

- Uncovers Hidden Inefficiencies: Benchmarking highlights deviations in throughput, downtime, and equipment utilization that traditional reporting often overlooks.

- Accelerates Technology Modernization: It provides clarity on automation, digital twin, and predictive maintenance adoption rates relative to global leaders.

- Improves Cost and Productivity Metrics: Enables comparison of unit costs, yield ratios, and manpower efficiency to inform strategic cost reduction.

- Guides Process Standardization: Helps harmonize operations across multi-plant or multi-geography setups by aligning to proven global best practices.

- Supports ESG Alignment: Evaluates performance across energy use, emissions, and waste parameters to promote sustainable manufacturing growth.

Benchmarking, when executed strategically, becomes a blueprint for operational excellence, empowering manufacturers to make evidence-based decisions and lead through continuous improvement.

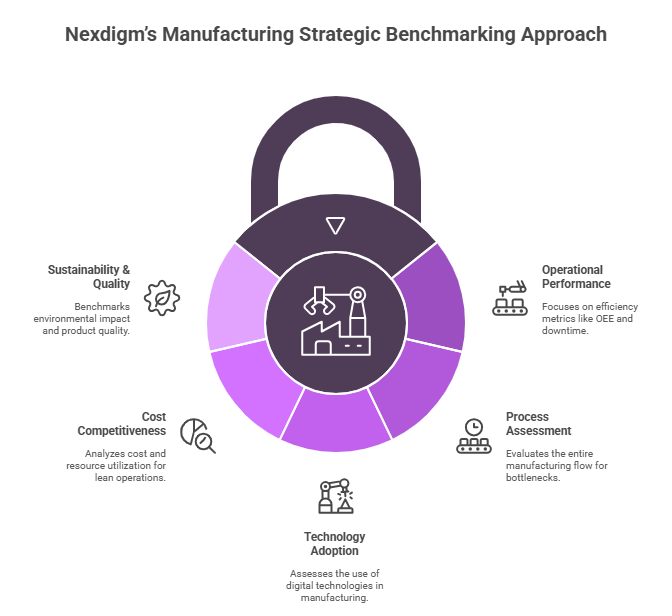

Nexdigm’s Manufacturing Strategic Benchmarking Approach

Nexdigm’s Manufacturing Strategic Benchmarking Approach is designed to help organizations quantify performance, identify best practices, and build continuous improvement frameworks anchored in global competitiveness. The methodology integrates competitive intelligence, operational analytics, and process diagnostics to deliver actionable insights across manufacturing functions.

Core Pillars of the Approach:

- Operational Performance Benchmarking: Compares key efficiency indicators such as OEE, yield, and downtime against global and regional peers to identify areas of underperformance and productivity improvement.

- Process and Value Chain Assessment: Evaluates the end-to-end manufacturing flow from procurement and production to logistics, to highlight bottlenecks, waste, and non-value-adding activities.

- Technology & Automation Benchmarking: Assesses readiness and adoption of digital manufacturing technologies, including robotics, IoT sensors, AI-based quality control, and predictive maintenance systems.

- Cost and Resource Competitiveness Analysis: Analyzes cost per unit, manpower utilization, and energy efficiency to ensure lean operations and optimal resource deployment.

- Sustainability and Quality Indexing: Benchmarks carbon efficiency, waste management, and defect rates to help organizations align operational excellence with environmental and quality standards.

Through this approach, Nexdigm enables manufacturers to translate benchmarking data into strategic roadmaps, improving asset utilization, accelerating digital transformation, and driving measurable operational gains across facilities and regions.

To take the next step, simply visit our Request a Consultation page and share your requirements with us.

Harsh Mittal

+91-8422857704