Manufacturing and construction industries are entering an era where digital transformation defines competitiveness. From IoT-enabled machinery and robotics to predictive analytics and digital twins, the concept of the Smart Factory has shifted from aspiration to necessity. Organizations that can integrate these technologies effectively are realizing measurable gains in productivity, quality, and sustainability.

Yet, the path to transformation is not straightforward. Many enterprises face a flood of new technologies, each promising automation, visibility, and efficiency. The challenge lies in choosing the right technologies, validating their impact, and integrating them seamlessly into existing operations without disrupting production or inflating costs.

This is where technology benchmarking becomes an essential enabler. By systematically comparing manufacturing technologies, automation tools, and digital systems across global peers, businesses gain a clear understanding of performance, interoperability, and ROI potential.

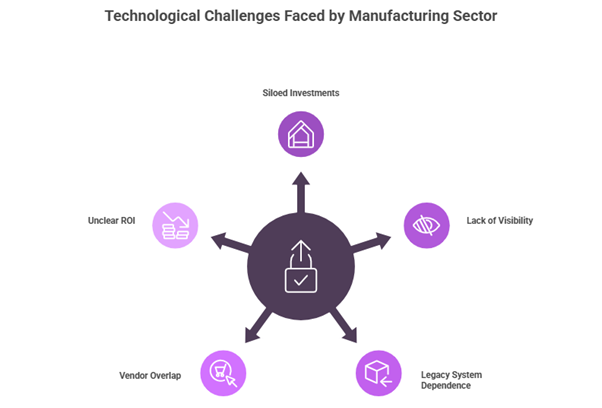

The Challenge: Fragmented Innovation and ROI Uncertainty

While the promise of Industry 4.0 continues to inspire transformation, many manufacturers and construction enterprises face a persistent roadblock of fragmented innovation. Technologies such as automation, IoT sensors, AI-based maintenance systems, and digital twins are often adopted in isolation, without a unified integration roadmap. The result is a patchwork of disconnected systems that underperform and fail to deliver expected returns.

Key challenges include:

- Siloed Technology Investments: Multiple departments adopt different systems, leading to duplication, incompatibility, and inconsistent data flows.

- Lack of Performance Visibility: Without comparative benchmarks, it becomes difficult to measure how technologies perform against global peers or justify their value beyond anecdotal outcomes.

- Legacy System Dependence: Integrating smart solutions with older production infrastructure often creates operational disruptions and cybersecurity vulnerabilities.

- Vendor Overlap and Confusion: With hundreds of solution providers offering similar capabilities, organizations struggle to distinguish innovation from redundancy.

- Unclear ROI Measurement: Many digital initiatives focus on deployment rather than impact, leaving enterprises unable to quantify gains in efficiency, cost savings, or output quality.

These inefficiencies not only dilute transformation ROI but also slow down innovation cycles. Enterprises end up with technology abundance but operational underperformance.

Technology benchmarking addresses this uncertainty by introducing an objective lens to technology decision-making. By comparing automation platforms, IoT ecosystems, and factory analytics tools based on real-world performance and peer adoption, manufacturers can identify what truly drives value and eliminate what doesn’t.

Nexdigm’s Manufacturing Technology Benchmarking Framework

Achieving a truly connected, data-driven manufacturing ecosystem requires a strategic roadmap grounded in comparative intelligence. Nexdigm’s Manufacturing Technology Benchmarking Framework enables enterprises to identify, evaluate, and integrate the right solutions that enhance efficiency, agility, and scalability across production networks.

By combining competitive intelligence, process analytics, and ROI benchmarking, Nexdigm helps manufacturers and construction firms make data-backed decisions that transform isolated digital initiatives into cohesive Smart Factory ecosystems.

Core Components of the Framework

- Market & Technology Landscape Mapping: Nexdigm begins by analyzing the Industry 4.0 ecosystem, identifying automation platforms, IoT networks, MES systems, and AI-driven maintenance solutions used by leading global manufacturers. This helps organizations understand emerging innovation trends and adoption benchmarks relevant to their industry.

- Performance & Capability Benchmarking: Each technology is assessed across parameters such as machine uptime, production throughput, energy efficiency, interoperability, and cybersecurity compliance. This ensures that technology investments are aligned with operational priorities and measurable performance outcomes.

- Vendor and Integration Intelligence: Nexdigm evaluates technology partners and solution providers based on their reliability, implementation record, regional support, and ability to integrate across legacy systems, helping clients shortlist best-fit vendors for smart factory integration.

- ROI and Cost-to-Value Modelling: By benchmarking cost structures and efficiency outcomes against peer manufacturers, the framework enables enterprises to predict ROI more accurately, minimize redundancies, and optimize investment allocation.

- Smart Factory Integration Roadmap: The final step converts insights into an actionable digital roadmap, prioritizing technologies that deliver the greatest operational impact and sequencing them for seamless, low-risk integration.

Through this structured benchmarking approach, Nexdigm helps organizations move beyond experimentation to measurable execution, ensuring that every technology investment drives efficiency, quality, and long-term competitiveness.

To take the next step, simply visit our Request a Consultation page and share your requirements with us.

Harsh Mittal

+91-8422857704