The global mining sector is undergoing a paradigm shift as it seeks to balance productivity, cost efficiency, and sustainability. With rising operational costs, volatile commodity prices, and growing pressure to reduce environmental impact, mining enterprises must look beyond traditional performance metrics. Achieving operational excellence today requires data-backed visibility across the entire mining value chain.

However, most mining operations continue to function in silos, where production, logistics, and energy management are measured independently. This fragmented approach often leads to underutilized equipment, excessive fuel consumption, and inefficiencies in haulage cycles.

End-to-End Operational Benchmarking provides a unified view of performance by comparing critical processes against global mining leaders. It enables organizations to measure tonnage per hour, fleet efficiency, and energy consumption per ton mined, helping identify improvement opportunities that directly impact cost, safety, and sustainability.

In an industry where every load counts and every kilowatt matters, operational benchmarking serves as a catalyst for continuous improvement, smarter resource use, and long-term competitiveness.

Understanding End-to-End Operational Benchmarking in Mining

End-to-end operational benchmarking provides a comprehensive performance view across the entire mining value chain, from pit operations to processing and energy management. Unlike isolated performance audits, it evaluates how effectively each operational layer contributes to overall output, cost control, and sustainability.

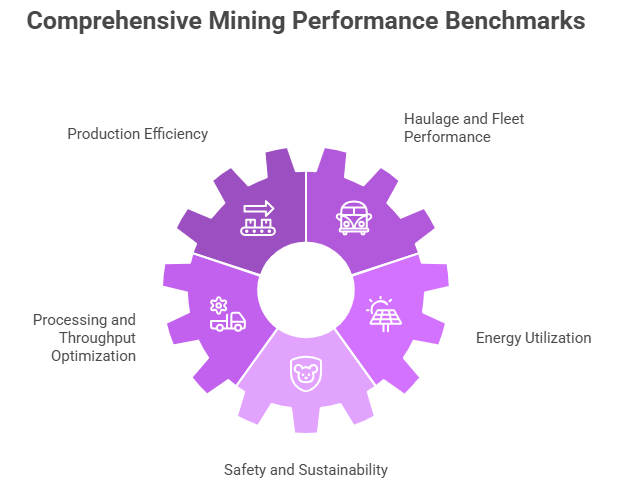

Key Focus Areas

- Production Efficiency: Benchmarks extraction rates, equipment utilization, downtime, and maintenance efficiency to improve tons mined per shift or per labor hour.

- Haulage and Fleet Performance: Analyzes truck cycle times, payload consistency, route optimization, and idle time to identify cost and time inefficiencies.

- Processing and Throughput Optimization: Evaluates ore recovery, plant yield, and process stability for better end-to-end production flow.

- Energy Utilization: Benchmarks power consumption per ton mined or processed and assesses renewable energy integration opportunities.

- Safety and Sustainability: Incorporates safety KPIs, environmental impact, and emission metrics into performance assessments.

Through this holistic view, mining companies can align production targets with operational efficiency, enabling data-driven decision-making that enhances productivity, reduces energy costs, and strengthens ESG compliance.

Nexdigm’s Mining Operations Benchmarking Framework

Nexdigm’s Mining Operations Benchmarking Framework is designed to help mining enterprises achieve sustained operational excellence by integrating analytics, process intelligence, and performance benchmarking across the full value chain. The framework evaluates how efficiently production, haulage, and energy functions interact, uncovering bottlenecks and opportunities for continuous improvement.

Core Components of the Framework

- KPI and Process Mapping: Establishes a unified set of performance metrics covering drilling, blasting, loading, hauling, processing, and maintenance. It ensures data consistency across sites and helps correlate machine utilization, tonnage output, and cost efficiency with strategic objectives.

- Production Performance Assessment: Benchmarks output per labor hour, equipment availability, and process yield to evaluate how effectively mine sites convert inputs into results. It identifies downtime causes and maintenance inefficiencies that affect production continuity.

- Haulage and Fleet Efficiency: Analyzes truck cycle times, route design, payload variance, and idle hours, using benchmarking insights to optimize haulage planning, minimize fuel usage, and improve scheduling accuracy.

- Energy Efficiency and Sustainability: Measures energy consumption per ton extracted, evaluates the performance of compressors, conveyors, and processing units, and benchmarks renewable integration and emission levels against global best practices.

- Improvement Roadmap: Translates findings into a structured action plan focused on process redesign, technology upgrades, predictive maintenance adoption, and workforce performance enhancement.

Through this comprehensive approach, Nexdigm helps mining companies transform operational benchmarking into a performance management tool, enabling better resource utilization, reduced operating costs, and improved ESG alignment across all mine sites.

To take the next step, simply visit our Request a Consultation page and share your requirements with us.

Harsh Mittal

+91-8422857704