The mining industry is entering a new era defined by automation, material efficiency, and sustainability. As operations expand into deeper, harsher, and more complex terrains, the demand for high-performance, durable, and energy-efficient equipment has grown exponentially. Equipment manufacturers today are expected to deliver machines that not only withstand extreme conditions but also optimize resource consumption and reduce operational emissions.

However, many manufacturers face a persistent challenge of balancing material strength, lifecycle durability, and cost efficiency without compromising on performance. While innovation in metallurgy, mechanical design, and hydraulics has advanced significantly, the absence of structured performance benchmarking often limits visibility into how products truly compare to global leaders.

This is where Product Benchmarking Intelligence becomes indispensable. By analyzing design architecture, material utilization, and performance metrics across competing OEMs, mining equipment manufacturers can uncover opportunities to enhance engineering efficiency, reduce material waste, and align with global sustainability standards.

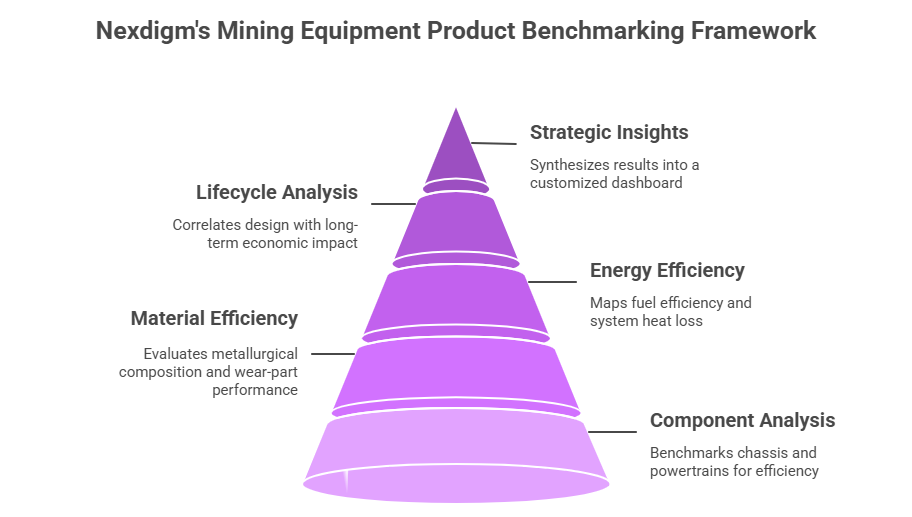

Nexdigm’s Mining Equipment Product Benchmarking Intelligence Framework

Nexdigm’s Mining Equipment Product Benchmarking Intelligence Framework offers a data-driven approach to evaluate how machinery performs in terms of design strength, material utilization, energy efficiency, and lifecycle reliability. By correlating engineering parameters with cost and sustainability outcomes, it enables equipment manufacturers to make smarter, evidence-based design and sourcing decisions.

- Component-Level Design and Structural Analysis: Nexdigm benchmarks chassis, hydraulics, powertrains, and frame structures across leading global OEMs to identify over-engineering, design inefficiencies, and material redundancies. This comparison helps manufacturers enhance strength-to-weight ratios, mechanical durability, and operational safety while optimizing material use.

- Material Efficiency and Durability Benchmarking: Our framework evaluates the metallurgical composition, coating technology, and wear-part performance of key components. By comparing resistance to abrasion, corrosion, and fatigue, we help manufacturers select materials that extend equipment life and reduce downtime.

- Energy and Operational Efficiency Mapping: Benchmarking parameters such as fuel efficiency, energy consumption per ton moved, and system heat loss reveals how effectively equipment converts power into productivity. These insights enable the design of more energy-efficient, low-emission, and high-yield machines suitable for modern mining conditions.

- Lifecycle and Cost Correlation Analysis: We analyze maintenance frequency, part replacement intervals, and total cost of ownership (TCO) to correlate design and material decisions with long-term economic impact. This ensures that every design improvement aligns with tangible value creation and cost savings.

- Strategic Insights and Implementation Roadmap: All benchmarking results are synthesized into a customized intelligence dashboard highlighting improvement priorities, supplier optimization opportunities, and design innovation paths. Nexdigm’s recommendations guide manufacturers in aligning product strategy with market demand, sustainability standards, and engineering best practices.

Through this framework, mining equipment producers gain the visibility needed to translate product comparisons into actionable innovation, improving performance, efficiency, and environmental compliance across their equipment portfolio.

Strategic Benefits for Mining Equipment Manufacturers

In a market where mining productivity, sustainability, and cost-efficiency determine competitive advantage, Nexdigm’s Product Benchmarking Intelligence enables equipment manufacturers to turn data into design excellence. By translating benchmarking insights into practical engineering and operational improvements, manufacturers can strengthen performance, reduce costs, and accelerate innovation.

- Engineering and Design Optimization: Benchmarking highlights areas where equipment can be redesigned for better strength-to-weight ratios, load handling, and material efficiency. This leads to lighter yet more durable machinery that performs optimally across diverse mining environments.

- Enhanced Material Utilization and Durability: By comparing wear rates, material grades, and component longevity, manufacturers can improve material selection, coating technologies, and part resilience.

- Energy and Sustainability Gains: Benchmarking energy consumption and fuel efficiency across leading OEMs helps identify energy-saving design adjustments and adoption of alternative power technologies. This directly supports ESG compliance and carbon footprint reduction, increasingly critical in global mining operations.

- Lifecycle Cost Reduction: Through detailed benchmarking of maintenance cycles, spare parts usage, and downtime patterns, Nexdigm helps clients achieve optimized total cost of ownership (TCO) while maintaining equipment reliability and uptime.

- Competitive Market Positioning: Manufacturers that integrate benchmarking insights into their R&D processes can market their products as performance-validated, sustainability-driven, and operationally superior. This differentiation strengthens their standing in both B2B procurement and investor evaluations.

By combining product performance analytics with sustainability and cost insights, Nexdigm enables mining equipment manufacturers to lead with innovation and efficiency in a highly competitive global market.

To take the next step, simply visit our Request a Consultation page and share your requirements with us.

Harsh Mittal

+91-8422857704