Manufacturers today operate in an environment of razor-thin margins, rising input costs, and relentless pressure to deliver higher quality at competitive prices. Global supply chain disruptions, customer demand for customization, and stricter compliance standards only add to the challenge. In this context, relying on incremental improvements is no longer sufficient to stay ahead.

To achieve sustainable growth, manufacturing leaders must adopt a structured approach that highlights where they truly stand against peers and industry leaders. Operations performance benchmarking serves as that lens, uncovering inefficiencies, identifying quality gaps, and providing a roadmap for improvement. When coupled with consulting expertise, benchmarking becomes a strategic enabler, allowing manufacturers to transform raw metrics into actionable strategies for boosting efficiency and elevating product quality.

Nexdigm’s Operations Performance Benchmarking

At Nexdigm, operations performance benchmarking is designed to be a strategic consulting tool that empowers manufacturers to align with global best practices and achieve sustainable growth. By blending competitive intelligence with actionable consulting support, we ensure organizations can identify gaps, prioritize improvement areas, and implement changes that drive both efficiency and quality.

Our approach focuses on:

- Comprehensive Benchmarking Frameworks – Mapping productivity, quality, and cost-efficiency metrics across global leaders and regional peers.

- Data Triangulation – Leveraging primary research, secondary sources, and proprietary databases for accurate, industry-specific insights.

- Actionable Insights – Going beyond numbers to provide roadmaps that address bottlenecks, inefficiencies, and compliance challenges.

- Implementation Support – Helping manufacturers translate benchmarks into measurable operational improvements such as shorter cycle times, higher yields, and reduced wastage.

This combination of intelligence and execution positions Nexdigm as a trusted partner for manufacturers seeking to improve operations while building long-term competitiveness in a disruptive global environment.

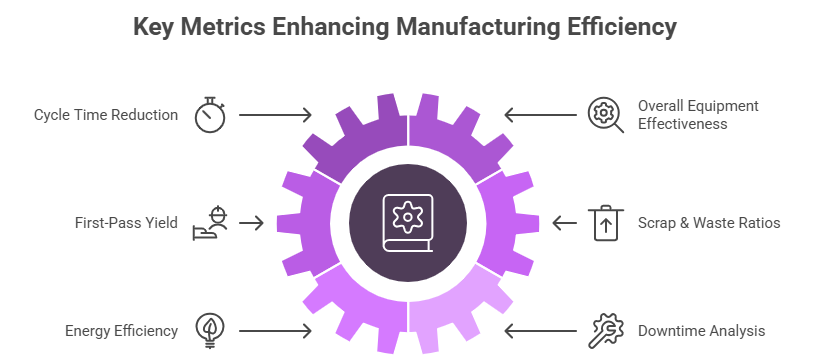

Key Metrics That Drive Efficiency and Quality

To truly compete in today’s global manufacturing environment, organizations must measure and benchmark the right operational metrics. These indicators provide visibility into where inefficiencies lie, how quality can be improved, and where strategic investments should be directed. Nexdigm’s approach focuses on metrics that directly impact both efficiency and product quality:

- Cycle Time Reduction – Tracking the total time taken for a production cycle helps identify bottlenecks and streamline workflows. Lower cycle times translate into faster throughput and better utilization of resources.

- Overall Equipment Effectiveness (OEE) – By measuring availability, performance, and quality of machinery, OEE highlights how well equipment is utilized compared to best-in-class benchmarks.

- First-Pass Yield (FPY) – A critical quality metric showing the percentage of products manufactured correctly without rework. Higher FPY means lower waste, reduced costs, and improved customer satisfaction.

- Scrap & Waste Ratios – Benchmarking material usage reveals inefficiencies in resource consumption and points to cost-saving opportunities through leaner processes.

- Energy Efficiency per Unit Output – With energy costs and sustainability pressures rising, comparing energy consumption against peers ensures both compliance and cost competitiveness.

- Downtime Analysis – Separating planned vs. unplanned downtime offers insights into equipment reliability and maintenance effectiveness, helping manufacturers reduce disruptions.

By continuously monitoring and improving on these metrics, manufacturers can achieve higher efficiency, deliver superior quality, and build resilience in an increasingly demanding market.

At Nexdigm, our Manufacturing Competitive Intelligence and Benchmarking solutions provide actionable strategies to help you achieve measurable results. Whether your goal is to reduce cycle times, optimize resource utilization, or strengthen product quality, we partner with you to build a roadmap for sustainable success.

To take the next step, simply visit our Request a Consultation page and share your requirements with us.

Harsh Mittal

+91 96549 82241