Rare earth elements (REEs) have become the backbone of the global transition toward clean energy, advanced electronics, and defense innovation. As demand for high-purity materials rises across industries like EV manufacturing, wind energy, and semiconductors, producers are under increasing pressure to improve product grade, extraction efficiency, and sustainability performance.

However, variability in ore composition, extraction yield, and process optimization continues to challenge even established mining operations. With growing scrutiny on environmental compliance and energy intensity, mining companies must demonstrate that their products meet international standards not just in quality, but in efficiency and responsibility.

This is where Product Benchmarking Intelligence becomes vital. By benchmarking ore grades, recovery efficiency, energy usage, and cost-per-output against global peers, rare earth producers can identify improvement areas, validate competitiveness, and align their operations with international performance norms.

Understanding Product Benchmarking in Rare Earth and Strategic Mining

In the rapidly evolving rare earth sector, success depends on efficiency, purity, and environmental stewardship. Product benchmarking provides a structured approach for mining enterprises to evaluate how their grades, extraction yields, and operational efficiencies compare against global industry standards. It transforms raw data into actionable intelligence that drives process optimization and sustainable growth.

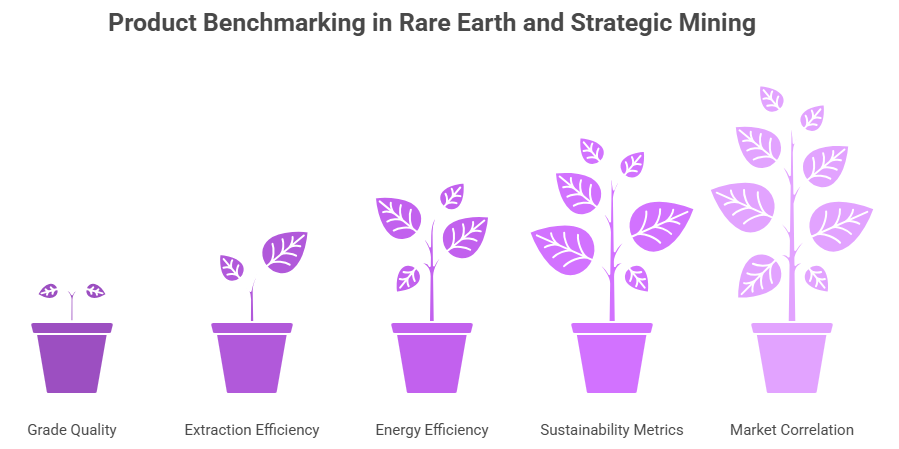

- Grade Quality and Concentrate Purity Benchmarking: Ore grade directly determines commercial viability. Benchmarking helps assess rare earth oxide (REO) concentration, impurity levels, and element distribution across comparable deposits or producers. This enables companies to gauge product competitiveness and identify opportunities for grade enhancement or process recalibration.

- Extraction and Recovery Efficiency: Benchmarking recovery rates, beneficiation yield, and reagent consumption helps measure extraction efficiency across mining and refining stages. These insights support targeted improvements in flotation, leaching, and solvent extraction, optimizing throughput and reducing waste.

- Energy and Cost Efficiency Analysis: Mining and refining rare earths are highly energy-intensive. Benchmarking energy consumption, reagent costs, and cost per ton of REO produced helps organizations improve unit economics and enhance competitiveness against global cost leaders.

- Sustainability and ESG Performance Metrics: With sustainability now central to investment and trade decisions, benchmarking evaluates carbon footprint, water usage, tailings management, and waste recovery systems. This helps producers align with global ESG frameworks while differentiating themselves through responsible extraction practices.

- Market and Value Correlation: Benchmarking also links technical performance with realized pricing, market acceptance, and offtake attractiveness. Understanding how product grade and recovery rates translate into export value allows companies to optimize pricing and strengthen commercial positioning.

In essence, product benchmarking enables rare earth producers to connect technical precision with market strategy, turning operational data into a foundation for global competitiveness.

Nexdigm’s Rare Earth Product Benchmarking Intelligence Framework

Nexdigm’s Rare Earth Product Benchmarking Intelligence Framework helps mining enterprises evaluate their performance across the full value chain. The framework integrates technical, environmental, and economic benchmarking to guide process improvements, strategic planning, and global market readiness.

- Grade and Concentrate Quality Assessment: Nexdigm benchmarks rare earth oxide (REO) content, impurity ratios, and elemental composition against global mining leaders. This comparison provides a clear understanding of how a company’s product quality aligns with international specifications and end-use requirements in EVs, electronics, and clean energy sectors.

- Extraction and Yield Performance Analysis: We assess beneficiation recovery rates, solvent extraction efficiency, and process throughput to identify operational gaps and potential for yield optimization. These insights help reduce processing losses and improve the overall material recovery rate, enhancing both profitability and resource utilization.

- Cost and Energy Efficiency Mapping: The framework compares cost-per-ton of concentrate, energy consumption, reagent usage, and waste treatment expenses with global benchmarks. This enables producers to pinpoint inefficiencies and design more cost-effective and energy-efficient production models.

- Sustainability and ESG Benchmarking: Nexdigm evaluates carbon intensity, water recycling practices, tailings disposal methods, and environmental compliance levels to align operations with international ESG standards. The results help companies validate sustainability claims and strengthen investor and stakeholder confidence.

- Strategic Insights Dashboard: All findings are consolidated into a comprehensive benchmarking intelligence dashboard, offering actionable recommendations for process optimization, technology upgrades, and cost-performance improvement. The insights also support policy engagement, export competitiveness, and sustainable certification initiatives.

Through this framework, Nexdigm enables rare earth producers to transform benchmarking insights into operational excellence, helping them compete globally while advancing toward a sustainable mining future.

To take the next step, simply visit our Request a Consultation page and share your requirements with us.

Harsh Mittal

+91-8422857704