Market Overview

The Asia Pacific commercial aircraft cabin seating market reached approximately USD ~ billion based on a recent historical assessment, driven by accelerating aircraft deliveries, expanding airline networks, and growing passenger volumes across emerging economies. Airlines are increasingly investing in lightweight seating platforms to reduce fuel consumption while improving cabin density and profitability. Continuous fleet modernization, rising premium travel demand, and the need for ergonomic passenger experiences are further strengthening procurement activity across both line-fit and retrofit programs.

China, India, Japan, and Singapore remain dominant due to strong aviation growth, large aircraft order pipelines, and advanced aerospace manufacturing ecosystems. China benefits from domestic production expansion, while India’s rapidly growing air travel demand supports aggressive fleet induction. Japan contributes through high-precision engineering capabilities, and Singapore functions as a major maintenance and retrofit hub. These countries collectively reinforce regional leadership by supporting airline expansion strategies and technological adoption within aircraft interiors.

Market Segmentation

By Seat Type

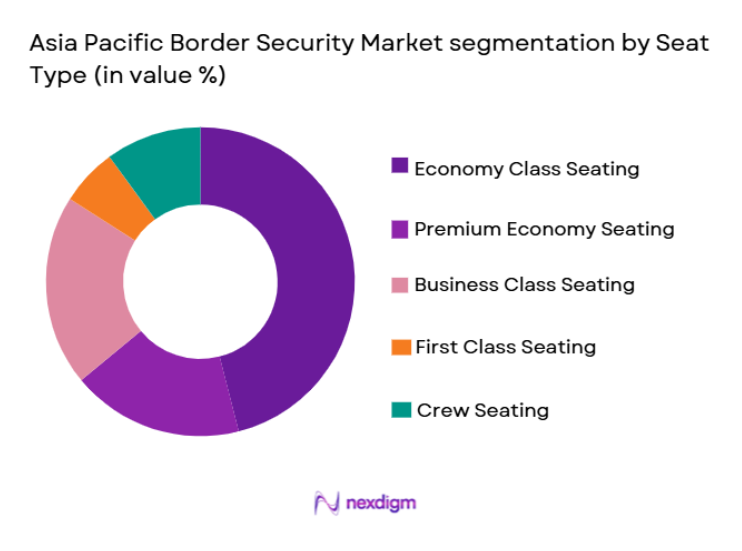

Asia Pacific Commercial Aircraft Cabin Seating market is segmented by seat type into economy class seating, premium economy seating, business class seating, first class seating, and crew seating. Recently, economy class seating has a dominant market share due to its high installation volume and essential role in revenue generation for airlines operating high-density routes. Carriers across the region prioritize maximizing passenger capacity to improve route profitability, particularly on short- and medium-haul networks. Slimline seat innovations allow airlines to increase seat count without significantly compromising comfort, further accelerating adoption. Low-cost carrier expansion has also reinforced demand for standardized economy configurations that simplify maintenance and reduce operational complexity. Additionally, fleet expansion strategies typically allocate the majority of cabin space to economy layouts, ensuring consistent procurement across new aircraft deliveries and refurbishment cycles. The segment benefits from continuous design enhancements focused on weight reduction and durability.

By Aircraft Type

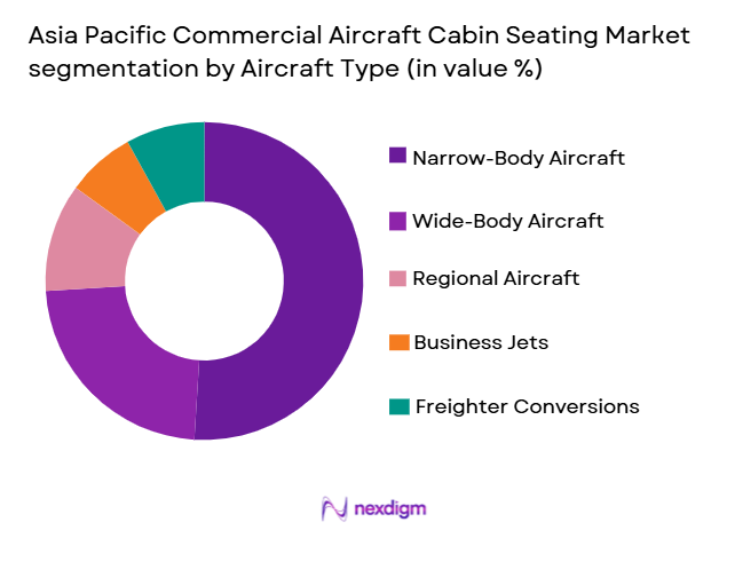

Asia Pacific Commercial Aircraft Cabin Seating market is segmented by aircraft type into narrow-body aircraft, wide-body aircraft, regional aircraft, business jets, and freighter conversions. Recently, narrow-body aircraft have a dominant market share due to their extensive deployment across domestic and regional travel corridors characterized by high passenger throughput. Airlines prefer these aircraft because they offer operational efficiency, quicker turnaround times, and lower per-seat costs, making them ideal for competitive markets. The rapid rise of low-cost carriers has further intensified narrow-body fleet expansion, directly increasing seating demand. Manufacturers are aligning production schedules with airline requirements, ensuring steady installation volumes. Moreover, frequent refurbishment cycles on short-haul aircraft sustain aftermarket opportunities for seat replacement and upgrades. Expanding connectivity between secondary cities also supports fleet additions, reinforcing the segment’s leadership in seating procurement across the region.

Competitive Landscape

The Asia Pacific commercial aircraft cabin seating market exhibits moderate consolidation, with established global seating manufacturers maintaining strong partnerships with airlines and OEMs. Competitive positioning is influenced by certification expertise, customization capabilities, and manufacturing scale. Long-term supply agreements and collaborative design initiatives enable major players to secure recurring revenue while supporting airline differentiation strategies through technologically advanced seating solutions.

| Company Name | Establishment Year | Headquarters | Technology Focus | Market Reach | Key Products | Revenue | Seat Engineering Capability |

| Safran Seats | 2018 | France | ~ | ~ | ~ | ~ | ~ |

| Collins Aerospace | 2018 | United States | ~ | ~ | ~ | ~ | ~ |

| RECARO Aircraft Seating | 1972 | Germany | ~ | ~ | ~ | ~ | ~ |

| Geven S.p.A. | 1984 | Italy | ~ | ~ | ~ | ~ | ~ |

| Acro Aircraft Seating | 2007 | United Kingdom | ~ | ~ | ~ | ~ | ~ |

Asia Pacific Commercial Aircraft Cabin Seating Market Analysis

Growth Drivers

Accelerating Aircraft Fleet Expansion Across Asia Pacific

Airlines throughout the region are expanding fleets to accommodate rising passenger demand driven by economic growth and increasing mobility. Large aircraft order backlogs are translating directly into higher seating installation volumes, particularly during line-fit production. Emerging markets are witnessing rapid aviation penetration, encouraging carriers to scale capacity aggressively. Manufacturers are responding by increasing output, which strengthens long-term procurement pipelines for seating suppliers. Government investments in airport infrastructure further enable airlines to introduce additional routes without operational bottlenecks. Fleet diversification strategies also require varied seating configurations, supporting product innovation. Leasing companies contribute by ordering aircraft with standardized seat platforms suitable for multiple operators. Retrofit programs complement new deliveries as airlines seek to maintain competitive cabin offerings. Technological advancements allow lighter seats that enhance fuel efficiency while preserving durability. Collectively, fleet expansion remains a foundational force sustaining consistent seating demand.

Rising Emphasis on Passenger Comfort and Premium Travel Experiences

Passenger expectations are evolving toward greater comfort, privacy, and personalization, prompting airlines to invest heavily in advanced seating concepts. Premium economy cabins are expanding because they provide an attractive balance between affordability and enhanced comfort. Business class suites featuring lie-flat functionality are increasingly deployed on long-haul routes to capture high-yield travelers. Airlines recognize that seating quality directly influences brand perception and customer loyalty. Competitive pressures are therefore accelerating design innovation across cushioning, adjustability, and in-seat technology integration. Connectivity features such as power outlets and entertainment interfaces further enhance perceived value. Manufacturers are developing modular architectures that enable airlines to tailor layouts efficiently. Improved materials contribute to both comfort and weight reduction, supporting operational goals. Retrofit activity is also rising as carriers upgrade older cabins to remain competitive. This sustained focus on passenger-centric design continues to propel seating investments.

Market Challenges

Stringent Certification and Safety Compliance Requirements

Aircraft seating must meet rigorous crashworthiness and flammability standards, requiring extensive testing before approval. Certification processes often extend development timelines, delaying product entry into service. Engineering modifications frequently trigger additional validation cycles, increasing program costs. Smaller manufacturers face barriers due to the technical resources needed to satisfy regulatory frameworks. Airlines demand proven reliability because seating failures can disrupt operations and compromise safety perception. Documentation and traceability requirements further intensify administrative workload. Regulatory variations across jurisdictions add complexity for globally active suppliers. Continuous updates to safety standards require ongoing design adaptation. These factors collectively elevate operational risk and constrain rapid innovation. Compliance therefore remains a critical challenge shaping competitive dynamics.

Volatile Raw Material and Component Supply Chains

Seating production depends on specialized alloys, composite materials, actuators, and electronic components sourced globally. Supply disruptions can delay manufacturing schedules and impact aircraft deliveries. Price fluctuations complicate long-term contract negotiations, particularly when suppliers operate under fixed pricing structures. Companies increasingly pursue multi-sourcing strategies, yet qualifying vendors requires strict testing protocols. Inventory buffers mitigate shortages but increase carrying costs. Rapid technological evolution also risks component obsolescence. Coordination across multiple supplier tiers introduces logistical complexity. Persistent uncertainty pressures margins and forecasting accuracy. Airlines may postpone upgrades during cost surges, affecting demand visibility. Strengthening supply resilience has therefore become a strategic priority for manufacturers.

Opportunities

Expansion of Premium Economy Seating Across Long-Haul Routes

Airlines are rapidly expanding premium economy cabins to capture travelers seeking enhanced comfort without business-class pricing. This segment generates higher yields than standard economy while maintaining efficient space utilization. Seating manufacturers benefit from increased demand for differentiated designs featuring greater recline and legroom. Long-haul network growth across Asia Pacific reinforces adoption of these configurations. Carriers are leveraging premium economy as a competitive differentiator on international routes. Customization opportunities allow suppliers to command stronger margins. Passenger willingness to pay for comfort continues to rise alongside disposable incomes. Collaborative design initiatives accelerate product innovation tailored to airline branding. Lightweight engineering ensures operational efficiency despite added features. This evolving cabin strategy creates durable growth prospects for seating providers.

Adoption of Smart Connected Seating Technologies

Digital transformation within aircraft cabins is driving integration of sensors, connectivity modules, and passenger interface technologies directly into seats. Smart seating can monitor usage patterns, enabling predictive maintenance that reduces downtime. Airlines gain access to data insights that support service optimization and targeted upgrades. Connectivity features improve traveler satisfaction while opening ancillary revenue channels. Manufacturers capable of delivering interoperable solutions gain competitive advantage in procurement decisions. Advances in power management enhance reliability without significantly increasing weight. Modular electronics simplify upgrades as technologies evolve. Partnerships between seating firms and technology providers are accelerating innovation cycles. As aircraft become increasingly connected environments, intelligent seating is expected to transition from premium feature to industry standard. This technological shift presents significant long-term opportunity.

Future Outlook

The Asia Pacific commercial aircraft cabin seating market is expected to expand steadily over the next five years, supported by sustained aircraft deliveries and airline modernization strategies. Advances in lightweight materials and smart seating technologies will enhance efficiency while improving passenger comfort. Regulatory emphasis on safety will continue shaping product innovation, encouraging certified design improvements. Rising premium travel demand and expanding regional connectivity are likely to reinforce procurement momentum across both line-fit and retrofit segments.

Major Players

- Safran Seats

- Collins Aerospace

- RECARO Aircraft Seating

- Geven S.p.A.

- Acro Aircraft Seating

- ZIM Aircraft Seating

- Thompson Aero Seating

- Expliseat

- Aviointeriors

- Mirus Aircraft Seating

- HAECO Cabin Solutions

- ST Engineering Aerospace

- Optimares

- Pitch Aircraft Seating Systems

- Jamco Corporation

Key Target Audience

- Commercial aircraft manufacturers

- Airline operators

- Aircraft leasing companies

- Maintenance repair and overhaul providers

- Cabin interior system suppliers

- Aerospace distributors

- Investments and venture capitalist firms

- Government and regulatory bodies

Research Methodology

Step 1: Identification of Key Variables

Core variables including fleet growth, airline procurement behavior, retrofit cycles, and seating technology adoption were identified through structured secondary research. Industry financial reports and aviation databases supported baseline demand assessment.

Step 2: Market Analysis and Construction

Top-down and bottom-up modeling techniques were applied to estimate market size and segment distribution. Aircraft production data was cross-verified with supplier output metrics to ensure analytical consistency.

Step 3: Hypothesis Validation and Expert Consultation

Insights from aerospace engineers, procurement specialists, and cabin integration professionals were used to validate assumptions related to seating demand and innovation trends, refining overall analytical accuracy.

Step 4: Research Synthesis and Final Output

Validated datasets were consolidated into a cohesive analytical framework emphasizing reliability and strategic relevance. The final report integrates quantitative evaluation with qualitative interpretation to support informed business planning.

- Executive Summary

- Research Methodology (Definitions, Scope, Industry Assumptions, Market Sizing Approach, Primary & Secondary Research Framework, Data Collection & Verification Protocol, Analytic Models & Forecast Methodology, Limitations & Research Validity Checks)

- Market Definition and Scope

- Value Chain & Stakeholder Ecosystem

- Regulatory / Certification Landscape

- Sector Dynamics Affecting Demand

- Strategic Initiatives & Infrastructure Growth

- Growth Drivers

Rising airline focus on passenger comfort and differentiation

Expansion of low-cost carrier fleets

Increasing aircraft deliveries across Asia Pacific

Shift toward lightweight seating technologies

Growth in aircraft retrofit and modernization programs - Market Challenges

Stringent safety certification requirements for seating systems

High development and customization costs

Supply chain disruptions impacting seat components

Weight constraints limiting design flexibility

Long approval timelines from aviation authorities - Market Opportunities

Expansion of premium economy seating across long-haul routes

Integration of smart and connected seating features

Growing demand for ergonomic lightweight seat designs - Trends

Adoption of slimline seating to increase seat density

Growing demand for lie-flat business class seats

Increased use of sustainable seat materials

Integration of in-seat power and connectivity

Modular seat architecture enabling faster cabin reconfiguration - Government Regulations & Defense Policy

Civil aviation crashworthiness standards for aircraft seats

Fire safety compliance requirements for seating materials

Passenger safety regulations shaping seat design - SWOT Analysis

- Stakeholder and Ecosystem Analysis

- Porter’s Five Forces Analysis

- Competition Intensity and Ecosystem Mapping

- By Market Value, 2020-2025

- By Installed Units, 2020-2025

- By Average System Price, 2020-2025

- By System Complexity Tier, 2020-2025

- By System Type (In Value%)

Economy Class Seating

Premium Economy Seating

Business Class Seating

First Class Suites

Crew Seating Systems - By Platform Type (In Value%)

Narrow-Body Aircraft

Wide-Body Aircraft

Regional Aircraft

Business Jets

Freighter Aircraft - By Fitment Type (In Value%)

Line Fit Seating

Retrofit Seating Programs

Cabin Reconfiguration Seating

Lightweight Seat Replacement

Premium Cabin Upgrades - By EndUser Segment (In Value%)

Full-Service Airlines

Low-Cost Carriers

Charter Airlines

Corporate Aviation Operators

Aircraft Leasing Companies - By Procurement Channel (In Value%)

Direct OEM Contracts

Tier-1 Seating Supplier Agreements

Aftermarket Procurement

Leasing Company Procurement

Third-Party Cabin Integrators - By Material / Technology (in Value %)

Lightweight Composite Seat Frames

Advanced Foam Cushioning

Slimline Seat Technology

Electric Actuation Systems

Smart Connected Seating

- Market structure and competitive positioning

- Market share snapshot of major players

- CrossComparison Parameters (Seat Weight Efficiency, Passenger Comfort Engineering, Customization Capability, Manufacturing Scale, Airline Partnerships, Certification Expertise, R&D Investment, Delivery Lead Time, Cost Competitiveness, Aftermarket Support)

- SWOT Analysis of Key Players

- Pricing & Procurement Analysis

- Key Players

RECARO Aircraft Seating

Safran Seats

Collins Aerospace

Geven S.p.A.

Acro Aircraft Seating

ZIM Aircraft Seating

HAECO Cabin Solutions

ST Engineering Aerospace

Aviointeriors

Expliseat

Mirus Aircraft Seating

Thompson Aero Seating

Optimares

Pitch Aircraft Seating Systems

Jamco Corporation

- Full-service airlines investing in premium seating differentiation

- Low-cost carriers prioritizing high-density seat configurations

- Leasing companies favoring standardized seating platforms

- Corporate operators demanding customizable luxury seating

- Forecast Market Value, 2026-2035

- Forecast Installed Units, 2026-2035

- Price Forecast by System Tier, 2026-2035

- Future Demand by Platform, 2026-2035