Market Overview

The Europe Aircraft Engine MRO market is projected to reach USD 13.4 billion based on a recent historical assessment. The market is driven by the growing demand for aircraft fleet maintenance, aging aircraft fleets requiring more frequent servicing, and the need for enhanced engine performance. Advancements in engine technology and increased air traffic are also contributing to the rising demand for maintenance, repair, and overhaul services. The market growth is further supported by the increasing focus on operational efficiency, safety standards, and compliance with environmental regulations.

Countries such as Germany, the United Kingdom, and France are dominant players in the Europe Aircraft Engine MRO market. These countries have well-established aerospace industries, including a strong presence of original equipment manufacturers (OEMs) and MRO service providers. Germany, with its central location in Europe and a leading aerospace industry, serves as a hub for both commercial and military aircraft engine MRO services. The UK and France also play vital roles, benefiting from their large fleets, significant air traffic volumes, and advanced MRO facilities that cater to both commercial and defense sectors.

Market Segmentation

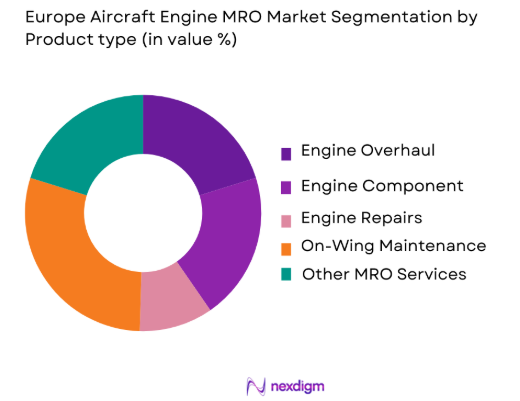

By Product Type

The Europe Aircraft Engine MRO market is segmented by product type into engine overhauls, engine component maintenance, engine repairs, on-wing maintenance, and other MRO services. Recently, engine overhauls have dominated the market share, driven by the growing need to extend the operational life of older engines and the increasing number of engines reaching their maximum operational hours. Engine overhauls are critical for maintaining engine performance, ensuring safety, and reducing the risk of failure. As airlines and operators look to minimize costs associated with new engine purchases, engine overhauls remain a key service offering in the MRO sector.

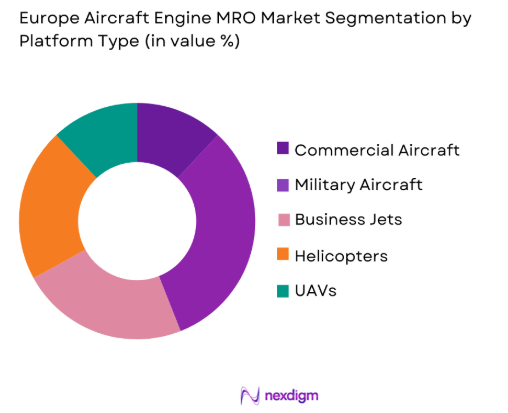

By Platform Type

The Europe Aircraft Engine MRO market is segmented by platform type into commercial aircraft, military aircraft, business jets, helicopters, and UAVs. Commercial aircraft platforms dominate the market due to the significant number of aircraft operating within Europe, coupled with the aging fleet and increasing air traffic. Commercial aviation requires extensive MRO services to ensure the safe operation of its engines, especially given the long hours of flight time and the regulatory requirements for engine maintenance. As the commercial aircraft fleet grows, so does the demand for engine MRO services, positioning this segment as the dominant force in the market.

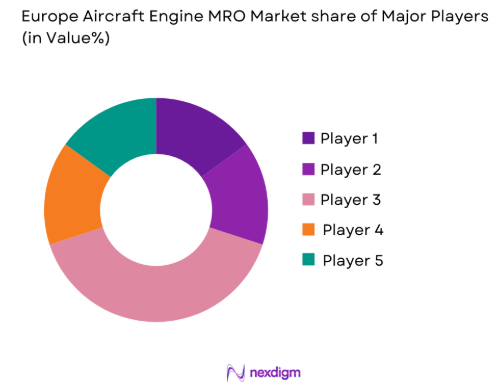

Competitive Landscape

The European aircraft engine MRO market is highly competitive, with several key players offering a broad range of maintenance services for both commercial and military aircraft. The market has seen consolidation, with major MRO providers expanding their capabilities through acquisitions and partnerships. Companies are focusing on improving operational efficiency and enhancing service offerings by incorporating advanced technologies like predictive maintenance and digital tracking of engine performance. The competitive landscape is dominated by players with strong infrastructure, expertise, and global reach, ensuring they can cater to a growing fleet of commercial and military aircraft.

| Company Name | Establishment Year | Headquarters | Technology Focus | Market Reach | Key Products | Revenue (USD) | Additional Market Parameter |

| Lufthansa Technik | 1951 | Hamburg, Germany | – | – | – | – | – |

| Rolls-Royce | 1906 | Derby, UK | – | – | – | – | – |

| Safran Aircraft Engines | 2005 | Paris, France | – | – | – | – | – |

| MTU Aero Engines | 1934 | Munich, Germany | – | – | – | – | – |

| ITP Aero | 1989 | Bilbao, Spain | – | – | – | – | – |

Europe Aircraft Engine MRO Market Analysis

Growth Drivers

Increased Air Traffic and Aircraft Fleet Growth

The growth in air traffic and the expansion of aircraft fleets is a significant driver of the Europe Aircraft Engine MRO market. With more aircraft in service, the need for reliable and timely engine maintenance increases, particularly as older aircraft require more frequent servicing. As Europe continues to experience strong demand for both domestic and international travel, airlines are expanding their fleets, which leads to greater demand for engine maintenance services. Additionally, the long operational hours and high utilization of commercial aircraft contribute to engine wear and tear, further increasing the need for regular engine overhauls, repairs, and maintenance. As the fleet grows and aging aircraft become a larger part of the fleet mix, MRO services for these engines will continue to drive market growth.

Technological Advancements in Engine Maintenance

Technological advancements in engine maintenance and repair are also contributing to the growth of the market. The integration of digital technologies, such as predictive maintenance, real-time monitoring, and advanced diagnostics, is revolutionizing the way engine maintenance is performed. By leveraging big data and AI, MRO providers can predict engine failure, plan maintenance schedules more efficiently, and minimize downtime. These innovations enhance the overall efficiency of engine maintenance and repair processes, reducing costs for operators while ensuring safety and performance. Additionally, new materials and processes, such as additive manufacturing and 3D printing of engine parts, are reducing costs and improving turnaround times for engine components. These technological advancements not only improve the service quality but also support the market’s growth by making engine maintenance more accessible and efficient.

Market Challenges

High Maintenance and Operational Costs

One of the primary challenges facing the Europe Aircraft Engine MRO market is the high cost of engine maintenance and repair services. The advanced technology and specialized skills required for maintaining modern aircraft engines come with significant costs. Engine overhauls, in particular, require large investments in parts, skilled labor, and specialized facilities. Additionally, the growing demand for more frequent maintenance due to the increasing number of aircraft in service puts additional pressure on MRO providers to maintain competitive pricing. Smaller players in the market may struggle to keep up with these high costs, while larger MRO providers benefit from economies of scale and the ability to invest in cutting-edge technologies. As a result, the cost of engine maintenance remains a significant challenge for both MRO service providers and aircraft operators.

Regulatory and Certification Hurdles

Another challenge in the Europe Aircraft Engine MRO market is the stringent regulatory and certification requirements imposed by aviation authorities such as the European Union Aviation Safety Agency (EASA) and the International Civil Aviation Organization (ICAO). These regulations govern the maintenance, repair, and overhaul of aircraft engines to ensure safety, reliability, and environmental sustainability. However, compliance with these regulations can be costly and time-consuming for MRO providers, as they must meet rigorous standards and undergo frequent audits. Furthermore, the introduction of new engine technologies and materials often requires updates to certification processes, which can delay the adoption of new MRO practices and systems. These regulatory hurdles can create barriers for smaller MRO service providers and slow down market expansion in certain regions.

Opportunities

Expansion of Aircraft Engine MRO in Emerging Markets

There is significant potential for growth in the Aircraft Engine MRO market through the expansion of services in emerging markets. As air travel continues to increase in regions such as Eastern Europe, the Middle East, and Africa, the demand for aircraft maintenance services, including engine MRO, is also on the rise. Emerging markets often have large numbers of aging aircraft that require more frequent servicing, creating opportunities for MRO providers to expand their operations in these regions. By establishing regional service centers, MRO providers can tap into new customer bases and benefit from the growing fleet sizes in emerging markets. Additionally, as many countries in these regions increase their aviation infrastructure investments, they are likely to prioritize the development of local MRO capabilities, creating further opportunities for international MRO providers to expand their services.

Growth in Aircraft Engine Leasing and Component Repair

The growing trend of aircraft engine leasing and component repair presents another opportunity for the market. Airlines and operators, particularly those in regions with high operational costs, are increasingly turning to engine leasing companies to manage engine lifecycles more efficiently. These companies provide leasing solutions that allow operators to reduce upfront capital expenditures and maintain access to the latest engine technologies. Additionally, the growing focus on sustainability and reducing the environmental impact of aviation is leading to an increased demand for component repair and refurbishment services. MRO providers can capitalize on these trends by offering more flexible and cost-effective services that meet the needs of a diverse range of customers, from low-cost carriers to major international airlines.

Future Outlook

The Europe Aircraft Engine MRO market is expected to continue its growth trajectory over the next five years, driven by technological advancements, increasing air traffic, and the demand for maintenance of both new and aging aircraft. As fleets expand and newer, more complex engines enter service, the need for advanced engine maintenance services will increase. Innovations in predictive maintenance, along with the rise of engine leasing and component repair services, will provide significant growth opportunities. The continued investment in MRO infrastructure and the shift toward sustainable aviation practices will also contribute to the market’s expansion.

Major Players

- Lufthansa Technik

- Rolls-Royce

- Safran Aircraft Engines

- MTU Aero Engines

- ITP Aero

- General Electric Aviation

- Pratt & Whitney

- Honeywell International

- Air France KLM Engineering & Maintenance

- Boeing

- Airbus

- United Technologies

- Rockwell Collins

- Collins Aerospace

- StandardAero

Key Target Audience

- Investments and venture capitalist firms

- Government and regulatory bodies

- Aircraft operators and fleet managers

- MRO service providers

- Aircraft manufacturers

- Engine leasing companies

- Aerospace technology developers

- Aviation maintenance organizations

Research Methodology

Step 1: Identification of Key Variables

Identify key drivers such as technological advancements, regulatory impacts, and market trends.

Step 2: Market Analysis and Construction

Gather and analyze market data from industry reports and expert opinions

Step 3: Hypothesis Validation and Expert Consultation

Consult industry professionals and stakeholders to validate assumptions and hypotheses.

Step 4: Research Synthesis and Final Output

Synthesize findings into actionable insights and a comprehensive market report.

- Executive Summary

- Research Methodology (Definitions, Scope, Industry Assumptions, Market Sizing Approach, Primary & Secondary Research Framework, Data Collection & Verification Protocol, Analytic Models & Forecast Methodology, Limitations & Research Validity Checks)

- Market Definition and Scope

- Value Chain & Stakeholder Ecosystem

- Regulatory / Certification Landscape

- Sector Dynamics Affecting Demand

- Strategic Initiatives & Infrastructure Growth

- Growth Drivers

Increasing Air Traffic and Fleet Expansion

Technological Advancements in Engine Maintenance

Growing Demand for Cost-Effective MRO Solutions - Market Challenges

High Maintenance and Operational Costs

Stringent Regulatory and Compliance Requirements

Complexity in Engine Component Maintenance - Market Opportunities

Growth in Demand for Engine Leasing and Component Repair

Expansion of Aircraft Engine MRO in Emerging Markets

Technological Innovations in Predictive Maintenance - Trends

Increasing Adoption of Digital MRO Solutions

Rise of Green and Sustainable Aviation Practices

Automation in Aircraft Engine Repair and Maintenance - Government Regulations

Regulations on Safety Standards and Engine Maintenance

Environmental Regulations on Emissions and Noise

Government Support for Aerospace and Aviation Innovation

- By Market Value 2020-2025

- By Installed Units 2020-2025

- By Average System Price 2020-2025

- By System Complexity Tier 2020-2025

- By System Type (In Value%)

Engine Overhaul

Engine Component Maintenance

Engine Repair

On-wing Maintenance

Other MRO Services - By Platform Type (In Value%)

Commercial Aircraft

Military Aircraft

Business Jets

Helicopters

UAVs - By Fitment Type (In Value%)

OEM Services

Aftermarket Services

Retrofit Services

Integrated Services

Standalone Services - By End User Segment (In Value%)

Aircraft Operators

MRO Service Providers

OEMs

Defense Contractors

Third-Party Maintenance Organizations - By Procurement Channel (In Value%)

Direct Procurement

OEM Sourcing

Third-Party Procurement

Bidding Contracts

Private Sector Procurement

- Market Share Analysis

- Cross Comparison Parameters (System Type, Platform Type, Procurement Channel, End User Segment, Fitment Type)

- SWOT Analysis of Key Competitors

- Pricing & Procurement Analysis

- Porter’s Five Forces

- Key Players

Rolls-Royce

General Electric Aviation

Pratt & Whitney

Safran Aircraft Engines

MTU Aero Engines

Air France KLM Engineering & Maintenance

Lufthansa Technik

Engine Alliance

IHI Corporation

CFM International

Honeywell Aerospace

Aero Engine Corporation of China

International Aero Engines

Airbus

Boeing

- Growing Need for Engine Overhaul Services

- MRO Providers Expanding Service Capabilities

- Increasing Focus on Predictive and Preventive Maintenance

- Airlines Modernizing Maintenance Practices

- Forecast Market Value 2026-2035

- Forecast Installed Units 2026-2035

- Price Forecast by System Tier 2026-2035

- Future Demand by Platform 2026-2035