Market Overview

The Israel aerospace flexible metal hose market is valued at approximately USD~ million in 2025. This market growth is driven by the rapid expansion of the aerospace sector in Israel, particularly in defense, UAVs, and space exploration. The demand for flexible metal hoses is supported by their application in critical aerospace systems, including fuel transfer lines, hydraulic systems, and environmental control systems. As Israel’s defense and aerospace budgets continue to rise, with key investments in advanced aerospace technologies, the demand for specialized aerospace components like flexible metal hoses remains strong. These hoses are engineered to withstand extreme pressure, temperature variations, and high mechanical stress, all crucial in the aerospace environment.

Israel, specifically cities such as Tel Aviv and Haifa, dominates the aerospace flexible metal hose market due to the country’s strong aerospace and defense industry. Israel Aerospace Industries (IAI), a major player in both military and commercial aerospace, leads the demand for specialized components such as flexible metal hoses. Haifa, being a hub for research and development in aerospace technologies, houses several companies involved in advanced manufacturing and integration of aerospace systems. Additionally, Israel’s strategic location in the Middle East and its technological collaborations with global aerospace manufacturers further solidify its position as a key player in the market.

Market Segmentation

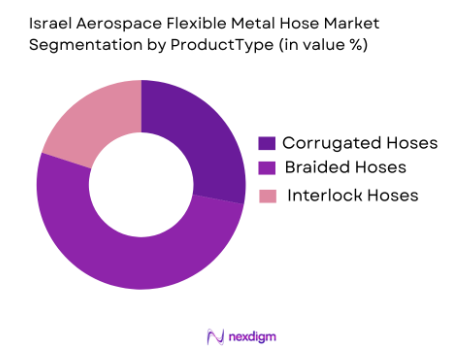

By Product Type

The Israel aerospace flexible metal hose market is segmented by product type into corrugated, braided, and interlock hoses. The braided flexible metal hoses dominate the market due to their superior strength, flexibility, and resistance to mechanical stress, making them ideal for use in aerospace applications that require high durability. These hoses are especially favored for high-pressure applications found in aerospace systems, such as fuel lines, hydraulic systems, and environmental control systems. Braided hoses offer enhanced resistance to vibration and fatigue, which is critical for ensuring the safety and longevity of aerospace components. The popularity of braided hoses is also attributed to advancements in materials such as stainless steel and alloys, which further improve their performance in demanding aerospace environments.

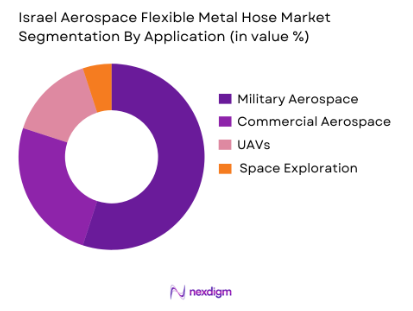

By Application

The market is segmented by application into military aerospace, commercial aerospace, UAVs, and space exploration. Military aerospace applications currently hold the largest market share. This dominance is driven by Israel’s robust defense spending and the need for highly reliable and durable components in military aircraft, helicopters, and unmanned aerial vehicles (UAVs). The Israeli government’s significant investment in defense technologies, coupled with the country’s focus on developing advanced military aviation systems, has created a steady demand for specialized aerospace components like flexible metal hoses. Additionally, the increasing development and adoption of UAVs for both military and commercial purposes further drive the growth of the military aerospace segment.

Competitive Landscape

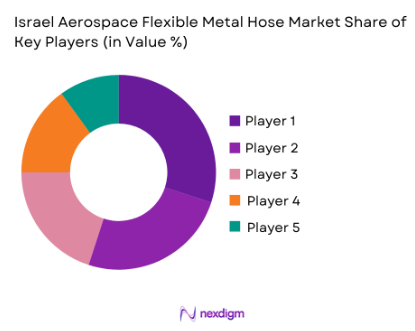

The Israel aerospace flexible metal hose market is highly competitive, with several major players dominating the landscape. Local manufacturers, such as Israel Aerospace Industries (IAI), are key drivers in the market, benefiting from strong government backing and partnerships with global aerospace firms. Other international players like Parker Hannifin and Eaton are also significant competitors due to their advanced technological capabilities and global presence. The market’s competitiveness is also enhanced by the continuous innovations in materials and hose manufacturing techniques, as well as strategic collaborations between local manufacturers and international aerospace companies.

| Company | Establishment Year | Headquarters | Product Range | Certifications | Key Markets | Production Capacity | Technological Capabilities |

| Israel Aerospace Industries | 1953 | Tel Aviv, Israel | Aerospace Hoses | ~ | ~ | ~ | ~ |

| Metline | 2001 | Tel Aviv, Israel | Metal Hoses | ~ | ~ | ~ | ~ |

| Inesco | 1985 | Haifa, Israel | Flexible Hoses | ~ | ~ | ~ | ~ |

| Parker Hannifin | 1917 | Cleveland, USA | Aerospace Hoses | ~ | ~ | ~ | ~ |

| Eaton | 1911 | Dublin, Ireland | Aerospace Hoses | ~ | ~ | ~ | ~ |

Drivers, Challenges & Opportunity Landscapes

Growth Drivers

Aircraft Production Growth

The growth in aircraft production plays a critical role in driving the demand for aerospace flexible metal hoses, which are used in various aircraft systems like fuel lines, hydraulic systems, and bleed air systems. According to the International Air Transport Association (IATA), the global fleet size is expected to increase significantly in the next few years, with over 50,000 commercial aircraft forecasted by 2026. The increase in aircraft production in Israel is largely driven by defense contracts and the aerospace sector’s growth. Israel’s defense sector alone saw a 5% increase in budget allocation for aerospace and defense in 2025, supporting a surge in aircraft manufacturing and, by extension, the demand for flexible metal hoses in these systems.

Defense Spending

Israel’s defense spending plays a pivotal role in boosting the aerospace flexible metal hose market, particularly for military aerospace applications. In 2025, Israel allocated approximately USD ~billion to defense, representing 5.5% of its GDP. This investment includes developing advanced technologies for defense systems and enhancing military aircraft fleets, which in turn drives the demand for highly durable, flexible metal hoses for military applications. Given the region’s geopolitical situation and security concerns, Israel’s military spending is expected to remain high, ensuring continuous investment in defense aerospace systems, which rely on high-performance components like flexible metal hoses.

Market Constraints

Raw Material Cost Volatility

The volatility of raw material costs, particularly the prices of stainless steel, titanium, and alloys, significantly affects the production costs of aerospace flexible metal hoses. As of early 2025, the cost of stainless steel has fluctuated due to disruptions in global supply chains and mining limitations. For instance, the price of stainless-steel rose by 15% between 2023 and 2024due to higher demand in industries such as construction and aerospace. Given that aerospace flexible metal hoses rely heavily on these materials, any price increase directly impacts production costs. Additionally, the Russia-Ukraine war has affected the supply of critical raw materials, exacerbating cost fluctuations for aerospace manufacturers globally.

Substitute Technologies

The development of substitute technologies for flexible metal hoses, such as composite hoses and advanced rubber-based materials, poses a challenge to the traditional flexible metal hose market. While these alternative materials offer advantages in weight and flexibility, they may not yet offer the same level of durability and pressure resistance required for aerospace applications. However, the research into alternative materials continues to grow. In 2024, companies are actively investing in the development of hybrid solutions combining metal and composites for aerospace use. Despite this, the lack of widespread adoption due to performance concerns keeps traditional flexible metal hoses in high demand for military and commercial aerospace applications.

Opportunities

eVTOL Hydrogen/Cryogenic Flexible Lines

The emergence of electric vertical take-off and landing (eVTOL) aircraft, particularly those powered by hydrogen, presents significant growth opportunities for the aerospace flexible metal hose market. Hydrogen fuel systems, which require specialized cryogenic flexible hoses, are becoming increasingly popular in the development of zero-emission aircraft. In 2025, Israel has launched several projects to develop hydrogen-powered aircraft for both military and commercial applications. These systems require flexible metal hoses capable of handling extreme cold temperatures, which opens a new niche for manufacturers of aerospace flexible metal hoses. Given the global push for sustainable aviation, the demand for these specialized hoses is poised for substantial growth as hydrogen adoption in aerospace increases.

Smart Hose Sensors

The integration of smart technology into aerospace flexible metal hoses represents a promising opportunity for market growth. Smart hose sensors that monitor pressure, temperature, and potential leaks in real-time are increasingly being integrated into aerospace applications. In 2024, a report by the Israeli Innovation Authority indicated that Israel is a leader in the development of smart materials and sensors, with several aerospace manufacturers experimenting with smart hose systems for military and commercial aircraft. The use of these sensors not only improves safety by providing continuous monitoring but also enables predictive maintenance, which can reduce operational costs and improve reliability. As the demand for smarter aerospace systems grows, the need for these advanced hose solutions will rise, driving market growth in the years ahead.

Future Outlook

The Israel aerospace flexible metal hose market is expected to show significant growth over the next decade. This growth will be driven by continuous advancements in aerospace technology, with increasing investments in the military and defense sector, as well as the growing demand for UAVs and space exploration projects. The trend towards lightweight and durable materials, coupled with the continuous need for high-performance components capable of withstanding extreme conditions, will further propel the demand for flexible metal hoses. Additionally, government policies supporting the aerospace and defense sectors will continue to provide a favorable environment for market growth.

Major Players

- Israel Aerospace Industries

- Metline

- Inesco

- Parker Hannifin

- Eaton

- Tite flex Aerospace

- Aero‑Flex Corp.

- Detroit Flex Defense

- Witzenmann

- Microflex Inc.

- Flexline

- Crescent Industries

- SAB North America

- Advanced Flexible Materials

- Hamilton Jet

Key Target Audience

- Investments and Venture Capitalist Firms

- Aerospace Manufacturing Companies

- Defense Contractors

- Government and Regulatory Bodies

- OEMs in Aerospace

- Aerospace Component Suppliers

- Aerospace Maintenance, Repair, and Overhaul Providers

- Aerospace Engineers and R&D Centres

Research Methodology

Step 1: Identification of Key Variables

This phase involves the identification and mapping of all relevant stakeholders in the Israel aerospace flexible metal hose market. Secondary research will be conducted to gather data from industry reports, databases, and market intelligence sources. Key variables such as product types, applications, and end-use sectors will be defined to structure the analysis.

Step 2: Market Analysis and Construction

In this step, historical data pertaining to the aerospace flexible metal hose market will be collected and analyzed. Market trends, technological advancements, and segment-specific performance will be reviewed to determine the growth trajectory and potential market size. Service provider and market penetration metrics will also be analysed to offer a comprehensive view of the market.

Step 3: Hypothesis Validation and Expert Consultation

Market hypotheses will be tested and validated through interviews with industry experts and key stakeholders in Israel’s aerospace sector. These consultations will provide insights into market dynamics, technological challenges, and the competitive landscape. Expert feedback will also help refine the market data and assumptions.

Step 4: Research Synthesis and Final Output

The final output will be developed by synthesizing all the gathered data, expert insights, and market analysis. This step involves creating detailed reports that offer actionable insights and a strategic roadmap for stakeholders interested in the Israel aerospace flexible metal hose market.

- Executive Summary

- Research Methodology (Market Definitions and Boundary Conditions, Assumptions and Standardization, Data Sources and Verification, Primary & Secondary Research Protocols, Data Normalization Processes, Sampling Error and Confidence Levels)

- Market Definition and Scope

- Market Genesis and Evolution

- Core Aerospace Functional Uses

- Aerospace Industry Linkages

- Supply Chain and Value

- Growth Drivers

Rising defense aviation modernization programs

Increased UAV and space platform production

Demand for high-reliability fluid transfer systems - Market Challenges

Stringent aerospace certification requirements

High material and manufacturing costs

Limited qualified supplier base - Market Opportunities

Expansion of domestic aerospace manufacturing

Growth in space and satellite missions

Adoption of advanced lightweight alloys - Trends

Shift toward custom-engineered hose assemblies

Integration of smart monitoring components

Increased localization of supply chains - Government Regulations

Compliance with Israeli defense procurement policies

Adherence to international aerospace standards

Export control and security regulations

- Israel Market Size, 2020-2025

- Regional Market Comparison, 2020-2025

- Global Market Benchmarks, 2020-2025

- Price Dynamics, 2020-2025

- By Hose Construction Type (In value%)

Corrugated, Bellows

Braided, Interlock

Expansion Joints

- By Material (In value%)

Stainless Steel

Inconel, Titanium

Alloy Grades

- By Operating Pressure (In value%)

Low, Medium

High Pressure

- By Application Function (In value%)

Fuel Lines, Cryogenic Transfer

Hydraulics, Pneumatics

Environmental Control

- By End‑Use Segment (In value%)

Commercial Aviation

Defense & Military Platforms

Space & Satellite Systems

UAV/eVTOL, MRO

- Market Share by Value & Volume

- Cross‑Comparison Parameters (Company Overview, Global Aerospace Certifications & Approvals, Product Range Breadth, Material Expertise, Technical Lead Time & Customization Capacity, Price Positioning, Distribution & Aftermarket Support Footprint, Installed Base in Key Platforms, R&D & Innovation Investment, Contract Wins with OEMs)

- SWOT Analysis of Key Competitors

- Pricing & Procurement Analysis

- Porter’s Five Forces

- Detailed Competitive Profiles

Metline

Inesco

Aero‑Flex Corp.

AMETEK FMH Aerospace

Parker Hannifin

Eaton Aerospace

Titeflex Aerospace

Detroit Flex Defense

CIA&D

Witzenmann

Flexline

Microflex Inc.

Israel Aerospace Industries

Local OEM Tier suppliers in Israel

Specialized MRO Flexible Hose Providers

- OEM Demand Drivers

- MRO & Aftermarket Utilization

- Buyer Budgeting & Procurement Cycles

- Technical Requirements & Pain Points

- Decision‑Making Functionality Priorities

- By Value & Volume Forecast to Market Maturity, 2026-2035

- Product & Material Mix Evolution, 2026-2035

- Application Growth Scenarios, 2026-2035