Market Overview

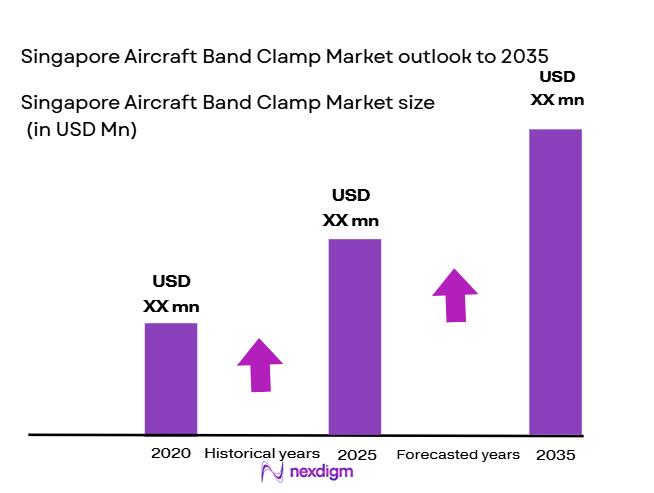

The Singapore aircraft band clamp market is valued at USD ~ million, based on a five-year historical analysis. This growth is primarily driven by the rapid expansion of the aerospace industry in Asia-Pacific, with Singapore playing a key role as a major hub for aviation and aerospace manufacturing. Factors such as government investments in aerospace infrastructure, the rise in aircraft production rates, and an increase in the number of air travel passengers have significantly contributed to the market’s growth. Additionally, the growing demand for high-quality, durable aircraft components further accelerates market dynamics, with aircraft band clamps playing a pivotal role in ensuring structural integrity.

Singapore, as a global aviation hub, holds a dominant position in the aircraft band clamp market due to its strategic location, robust aerospace infrastructure, and strong government support for the aviation sector. Other contributing countries to the market include Japan, South Korea, and China, all of which have highly developed aerospace industries and invest heavily in both military and commercial aviation. Singapore, with its advanced MRO (Maintenance, Repair, and Overhaul) services and leading aircraft manufacturers, remains a key player in driving regional demand for aircraft components, particularly for aircraft band clamps.

Market Segmentation

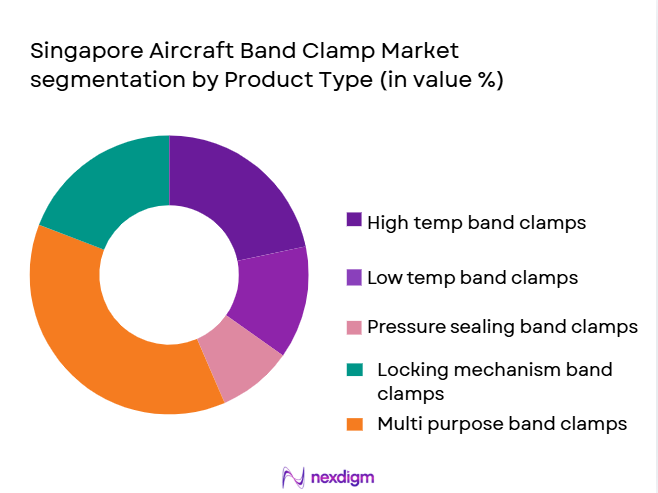

By Product Type

The Singapore aircraft band clamp market is segmented by system type into commercial aircraft, military aircraft, general aviation, cargo aircraft, and helicopters. The commercial aircraft segment dominates the market, driven by the growing demand for passenger flights and global travel recovery. The increase in air traffic, especially in Asia, has led to more aircraft being produced, which consequently raises the need for high-quality aircraft band clamps. Commercial aircraft are equipped with advanced systems that require robust, reliable, and durable parts, further increasing demand for band clamps that ensure safe and efficient operation.

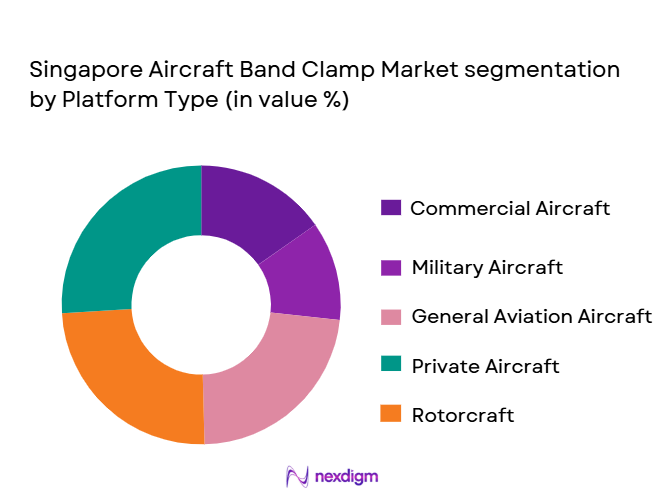

By Platform Type

The market is also segmented by platform type, including fixed-wing aircraft, rotary-wing aircraft, unmanned aerial vehicles (UAVs), hybrid aircraft, and advanced air mobility (AAM) aircraft. Fixed-wing aircraft, being the most common in both commercial and military aviation, holds the largest share of the platform type segment. This dominance is due to the significant presence of commercial airlines and defense forces relying heavily on fixed-wing aircraft. In addition, the increase in demand for UAVs in various sectors such as surveillance and logistics is gradually increasing its market share, offering strong growth prospects in the coming years.

Competitive Landscape

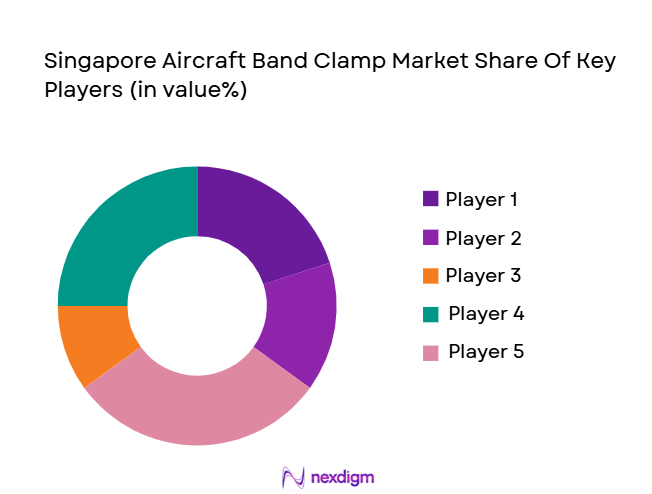

The Singapore aircraft band clamp market is dominated by a few key players, such as AeroClip Technologies, Tronair, and Collins Aerospace. These companies are prominent due to their extensive experience, cutting-edge technology, and strong distribution networks. Their market leadership is further strengthened by strategic partnerships with key aircraft manufacturers and maintenance service providers. As a result, they enjoy a substantial share in the market, contributing to product innovation and the development of more efficient, lightweight, and cost-effective aircraft band clamps.

| Company | Establishment Year | Headquarters | Product Innovation | Customer Base | Regional Reach | Pricing Strategy |

| AeroClip Technologies | 2005 | Singapore | ~ | ~ | ~ | ~ |

| Tronair | 1982 | USA | ~ | ~ | ~ | ~ |

| Collins Aerospace | 1932 | USA | ~ | ~ | ~ | ~ |

| Satair | 2006 | Denmark | ~ | ~ | ~ | ~ |

| Lisi Aerospace | 1970 | France | ~ | ~ | ~ | ~ |

Singapore Aircraft Band Clamp Market Dynamics

Growth Drivers

Increasing Demand for Commercial Aircraft

The global demand for commercial aircraft is increasing due to the recovery in air travel post-pandemic and the growth in passenger traffic. According to the International Civil Aviation Organization (ICAO), the number of global air passengers reached ~ billion in 2023, which marked a strong rebound from the pandemic’s lows. The growing middle class in emerging economies, especially in Asia-Pacific, is expected to further fuel this demand. ICAO forecasts a ~% growth in annual passenger traffic through 2026, creating significant demand for aircraft and components, such as band clamps, essential for both new aircraft production and maintenance activities.

Rise in Military Aircraft Modernization Programs

Military aircraft modernization programs are gaining momentum globally, particularly in the Asia-Pacific region, including Singapore. In 2023, the global defense spending reached approximately USD ~ trillion, with a significant portion directed toward upgrading military aircraft fleets. The Singapore Ministry of Defence (MINDEF) has allocated substantial funds to enhance its air force capabilities, including modernizing fighter jets and transport aircraft. This surge in military aircraft upgrades is driving demand for high-quality components like aircraft band clamps, which are critical for ensuring the structural integrity and safety of these advanced systems.

Growing Focus on Aircraft Safety and Durability

As the aviation industry continues to prioritize safety and durability, there is an increasing focus on the quality and performance of aircraft components. In response to this demand, global aviation safety regulations have become stricter. The European Union Aviation Safety Agency (EASA) and the Federal Aviation Administration (FAA) have issued new directives requiring enhanced safety measures for aircraft parts. For instance, in 2024, EASA introduced regulations to address component reliability, directly impacting the demand for high-durability parts like band clamps, which ensure long-term safety and performance in commercial and military aircraft.

Market Challenges

High Cost of Aircraft Band Clamps

The high cost of manufacturing aircraft band clamps poses a challenge for the market, driven by the stringent quality and material standards required for aerospace components. According to a report by the World Bank, the cost of raw materials like titanium and steel has risen by ~% year-on-year in 2024, contributing to the overall increase in production costs. Aircraft band clamps, which must adhere to these high standards, are directly impacted by these cost fluctuations. Additionally, the complexity of the manufacturing process, involving precision engineering and rigorous testing, further drives up costs, affecting the overall affordability of components.

Stringent Regulatory and Certification Requirements

The aircraft components market faces challenges due to the increasingly stringent regulatory environment. In 2024, the FAA and EASA have implemented updated certification procedures that demand more detailed testing and documentation for components used in both commercial and military aircraft. These regulations ensure safety but can lead to delays in the production and approval of new components like aircraft band clamps. For instance, compliance with the FAA’s newly updated certification rules, which came into effect in January 2024, requires manufacturers to provide extensive lifecycle data, adding time and cost to the development process.

Supply Chain Disruptions in the Aerospace Industry

The aerospace industry continues to experience supply chain disruptions, which have been exacerbated by geopolitical tensions and logistical challenges. The COVID-19 pandemic created significant delays in the delivery of raw materials, and these issues persist in 2024. According to the World Trade Organization (WTO), global shipping costs remain elevated by approximately ~% over pre-pandemic levels. The aerospace sector is particularly vulnerable due to its reliance on high-precision components that require timely delivery. Any delay in the supply of materials or parts, such as titanium alloys used in aircraft band clamps, can cause production delays, affecting the overall market.

Market Opportunities

Technological Innovations in Aircraft Band Clamps

Technological innovations are poised to drive future growth in the Singapore aircraft band clamp market. In 2024, several aerospace manufacturers are investing in research and development to create lighter, more durable, and corrosion-resistant aircraft band clamps. Advanced materials such as carbon fiber composites and titanium alloys are being increasingly used, offering superior strength-to-weight ratios and resistance to environmental stressors. With the growing emphasis on fuel efficiency and reduced maintenance costs, these innovations will enhance the appeal of aircraft band clamps, making them a critical part of modern aviation systems. The ongoing trend toward lightweight and high-performance materials is expected to sustain the demand for high-tech components in the coming years.

Expansion of Aircraft Fleets in Emerging Markets

Emerging markets, particularly in Asia-Pacific, continue to expand their aircraft fleets to meet the growing demand for air travel. In 2024, Asia-Pacific is forecasted to account for over ~% of global air traffic, with countries like India, China, and Southeast Asia seeing strong increases in new aircraft purchases. This trend is further supported by investments in airport infrastructure and air traffic management. As these countries modernize their aviation fleets, there will be an increased demand for aircraft components, including band clamps, to ensure the safety and performance of new aircraft. The expansion of these fleets in emerging markets offers significant growth opportunities for manufacturers of aviation parts.

Future Outlook

Over the next ~ years, the Singapore aircraft band clamp market is expected to witness steady growth driven by increasing aircraft production, the expansion of air travel, and growing investment in defense aerospace programs. Innovations in materials, including lightweight and corrosion-resistant alloys, will also play a pivotal role in the market’s future expansion. The rise of unmanned aerial vehicles and hybrid aircraft, as well as the demand for more efficient, cost-effective components, will provide ample opportunities for market players to capitalize on emerging trends and technologies.

Major Players

- AeroClip Technologies

- Tronair

- Collins Aerospace

- Satair

- Lisi Aerospace

- Eaton Aerospace

- Amphenol Aerospace

- Honeywell Aerospace

- Safran

- United Technologies

- Spirit AeroSystems

- Dynatech

- Kaman Aerospace

- Harris Corporation

- Moog Aerospace

Key Target Audience

- Aircraft Manufacturers

- Airlines & Airline Operators

- Military and Defense Agencies (e.g., Singapore Armed Forces)

- Aviation Maintenance, Repair, and Overhaul (MRO) Providers

- Aircraft Parts and Components Suppliers

- OEMs in Aerospace

- Investment and Venture Capitalist Firms

- Government and Regulatory Bodies (e.g., Civil Aviation Authority of Singapore)

Research Methodology

Step 1: Identification of Key Variables

The initial phase involves constructing an ecosystem map encompassing all major stakeholders within the Singapore aircraft band clamp market. This step is underpinned by extensive desk research, utilizing secondary and proprietary databases to gather comprehensive industry-level information. The primary objective is to identify and define the critical variables that influence market dynamics.

Step 2: Market Analysis and Construction

This phase involves compiling and analyzing historical data pertaining to the Singapore aircraft band clamp market, including the assessment of aircraft production rates, demand for MRO services, and revenue generation. Additionally, the analysis of supplier networks, cost structures, and market penetration will be undertaken to refine market estimations.

Step 3: Hypothesis Validation and Expert Consultation

Market hypotheses will be validated through consultations with industry experts via telephone interviews and surveys. These consultations will provide operational and financial insights from aerospace manufacturers, MRO providers, and component suppliers, which will be instrumental in confirming market projections.

Step 4: Research Synthesis and Final Output

In the final phase, we will engage directly with aircraft band clamp manufacturers to gain detailed insights into their production techniques, material innovations, customer preferences, and growth strategies. This will help verify and complement the data gathered from the initial market construction, ensuring a comprehensive and accurate analysis of the Singapore aircraft band clamp market.

- Executive Summary

- Singapore Aircraft Band Clamp Research Methodology

(Definitions, Scope, Industry Assumptions, Market Sizing Approach, Primary & Secondary Research Framework, Data Collection & Verification Protocol, Analytic Models & Forecast Methodology, Limitations & Research Validity Checks)

- Market Definition and Scope

- Value Chain & Stakeholder Ecosystem

- Regulatory / Certification Landscape

- Sector Dynamics Affecting Demand

- Strategic Initiatives & Infrastructure Growth

- Growth Drivers

Increasing Demand for Commercial Aircraft

Rise in Military Aircraft Modernization Programs

Growing Focus on Aircraft Safety and Durability - Market Challenges

High Cost of Aircraft Band Clamps

Stringent Regulatory and Certification Requirements

Supply Chain Disruptions in the Aerospace Industry - Market Opportunities

Technological Innovations in Aircraft Band Clamps

Expansion of Aircraft Fleets in Emerging Markets

Increased Investment in Unmanned Aerial Vehicle (UAV) Technology - Trends

Shift Towards Lightweight and Corrosion-Resistant Materials

Rising Adoption of Smart Aircraft Band Clamps

Growth of Sustainable Aviation Technologies

- Government Regulations & Defense Policy

FDI Rules

Offset Obligations

Export Licenses - SWOT Analysis (Capability Strengths, Cost Vulnerabilities, Competitive Pressures)

Porter’s Five Forces (Procurement Power, Supplier Concentration, Substitutes, Barriers to Entry)

- By Market Value 2020-2025

- By Installed Units 2020-2025

- By Average System Price 2020-2025

- By System Complexity Tier 2020-2025

- By System Type (In Value%)

Clamp Bands for Commercial Aircraft

Clamp Bands for Military Aircraft

Clamp Bands for General Aviation

Clamp Bands for Cargo Aircraft

Clamp Bands for Helicopters - By Platform Type (In Value%)

Fixed-Wing Aircraft

Rotary-Wing Aircraft

Unmanned Aerial Vehicles (UAVs)

Hybrid Aircraft

Advanced Air Mobility (AAM) Aircraft - By Fitment Type (In Value%)

Original Equipment Manufacturer (OEM) Fitments

Aftermarket Fitments

Retrofit Fitments

Maintenance, Repair, and Overhaul (MRO) Fitments

Custom Fitments - By EndUser Segment (In Value%)

Commercial Aviation Operators

Military Aviation Operators

Aircraft Manufacturers

MRO Service Providers

Government and Defense Agencies - By Procurement Channel (In Value%)

Direct Purchase from Manufacturers

Third-Party Distributors

Online Procurement Channels

Government Contracts

MRO Service Partnerships

- Market Share Analysis

- CrossComparison Parameters

(Market Share by Region, Product Performance, Innovation Index, Customer Satisfaction, Price Sensitivity) - SWOT Analysis of Key Competitors

- Pricing & Procurement Analysis

- Key Players

AeroClip Technologies

Tronair

Stabilus

Lisi Aerospace

Satair

Eaton Aerospace

Collins Aerospace

Amphenol Aerospace

Honeywell Aerospace

Safran

United Technologies

Spirit AeroSystems

Dynatech

Kaman Aerospace

Harris Corporation

- Expansion of Aircraft Fleets in Asia-Pacific

- Adoption of Advanced Aircraft Maintenance Techniques

- Government Investments in Aerospace Industry

- Growth in Aircraft Leasing Market

- Forecast Market Value 2026-2035

- Forecast Installed Units 2026-2035

- Price Forecast by System Tier 2026-2035

- Future Demand by Platform 2026-2035