Market Overview

Based on a recent historical assessment, the Singapore Commercial Aircraft Overhead Stowage Bins Market generated USD ~ million in total revenue, supported by steady aircraft deliveries, cabin retrofitting programs, and sustained maintenance activity across the country’s aviation ecosystem. Demand was driven by narrow-body fleet expansion, mandatory cabin safety compliance, and weight-reduction initiatives by airlines seeking operating efficiency. Retrofit demand from in-service aircraft further reinforced procurement volumes. This valuation is supported by civil aviation statistics from CAAS, procurement disclosures from ST Engineering Aerospace, and OEM cabin interior revenue disclosures aggregated for Singapore-based operations.

Based on a recent historical assessment, Singapore emerged as the dominant national market, led by the concentration of airline headquarters, MRO hubs, and aircraft leasing operations in Singapore city. Seletar and Changi aviation clusters host major cabin integration and retrofit facilities, enabling rapid adoption of upgraded stowage systems. Regional influence from Southeast Asian airline fleets funnels procurement decisions through Singapore-based lessors and integrators. Strong regulatory oversight, advanced infrastructure, and proximity to major OEM supply chains collectively reinforce Singapore’s dominance in commercial aircraft cabin component adoption.

Market Segmentation

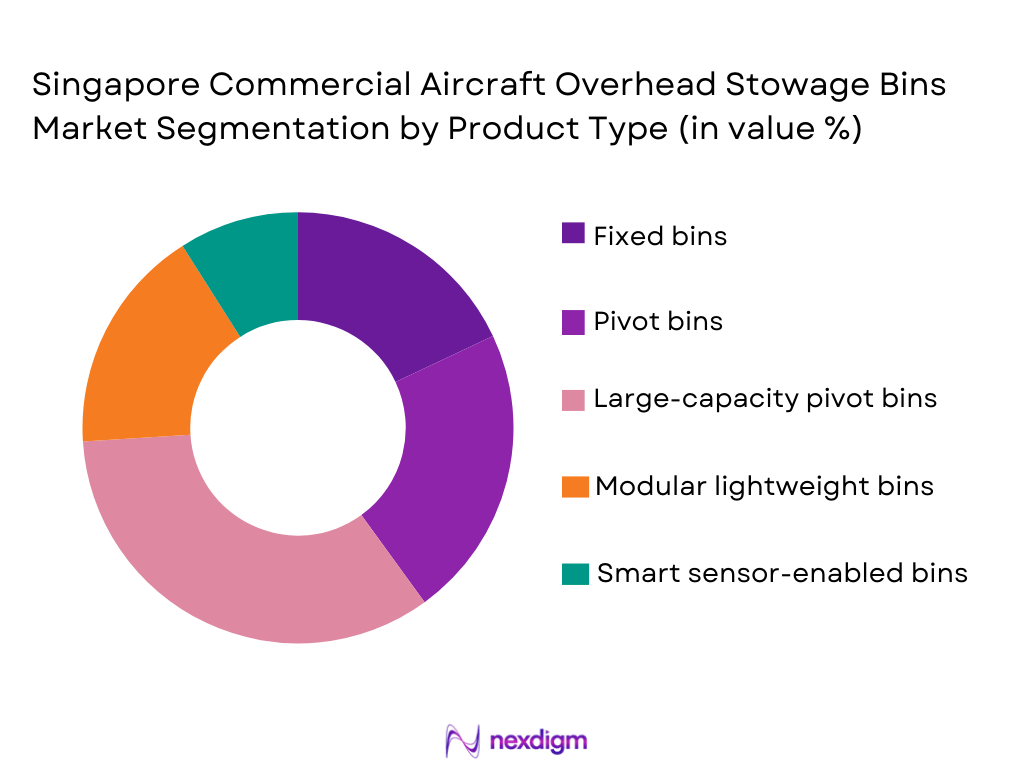

By Product Type

Singapore Commercial Aircraft Overhead Stowage Bins Market is segmented by product type into fixed bins, pivot bins, large-capacity pivot bins, modular lightweight bins, and smart sensor-enabled bins. Recently, large-capacity pivot bins have a dominant market share due to airline preference for increased carry-on capacity, improved passenger convenience, and compatibility with single-aisle aircraft cabin densification. Airlines operating high-frequency regional routes prioritize these bins to reduce boarding time and improve customer experience. OEM standardization of pivot mechanisms, proven reliability, and regulatory certification familiarity further accelerate adoption. Leasing companies also favor this sub-segment due to higher asset remarketing value and broad fleet applicability across multiple aircraft platforms.

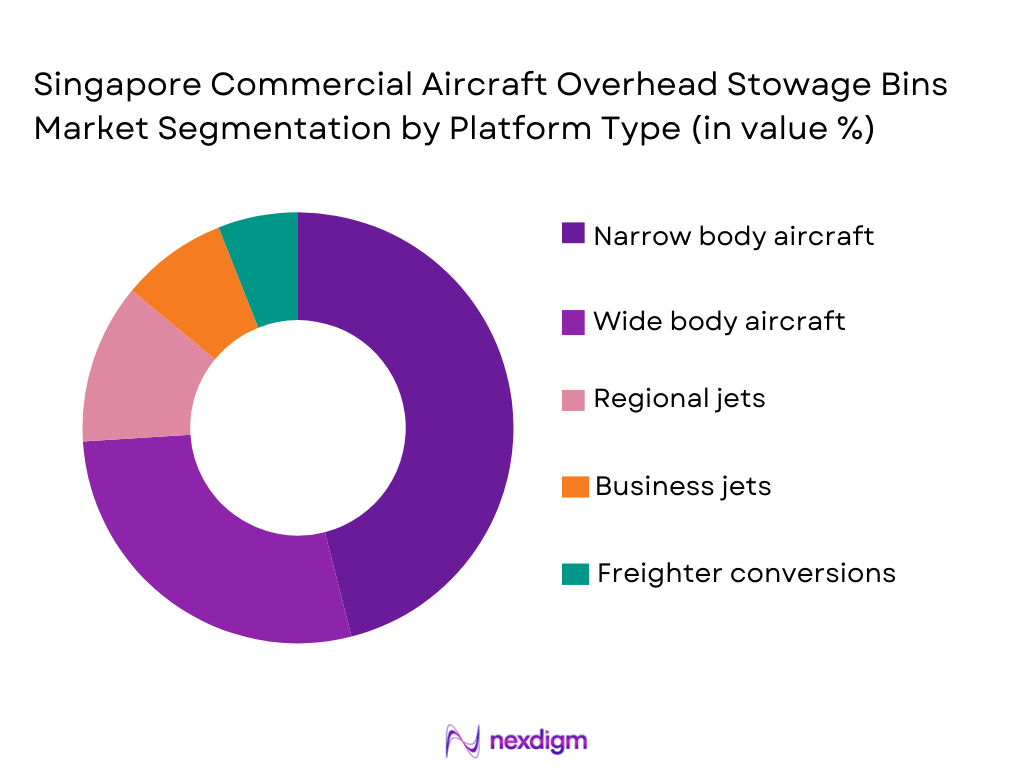

By Platform Type

Singapore Commercial Aircraft Overhead Stowage Bins Market is segmented by platform type into narrow-body aircraft, wide-body aircraft, regional jets, business jets, and freighter conversions. Recently, narrow-body aircraft platforms have a dominant market share due to their extensive deployment on short-haul and regional routes operated from Singapore. High utilization rates, frequent cabin refresh cycles, and large installed bases drive continuous demand for overhead stowage upgrades. Low-cost and full-service carriers alike prioritize narrow-body fleets for efficiency, making this platform the primary driver of volume demand for standardized stowage bin systems.

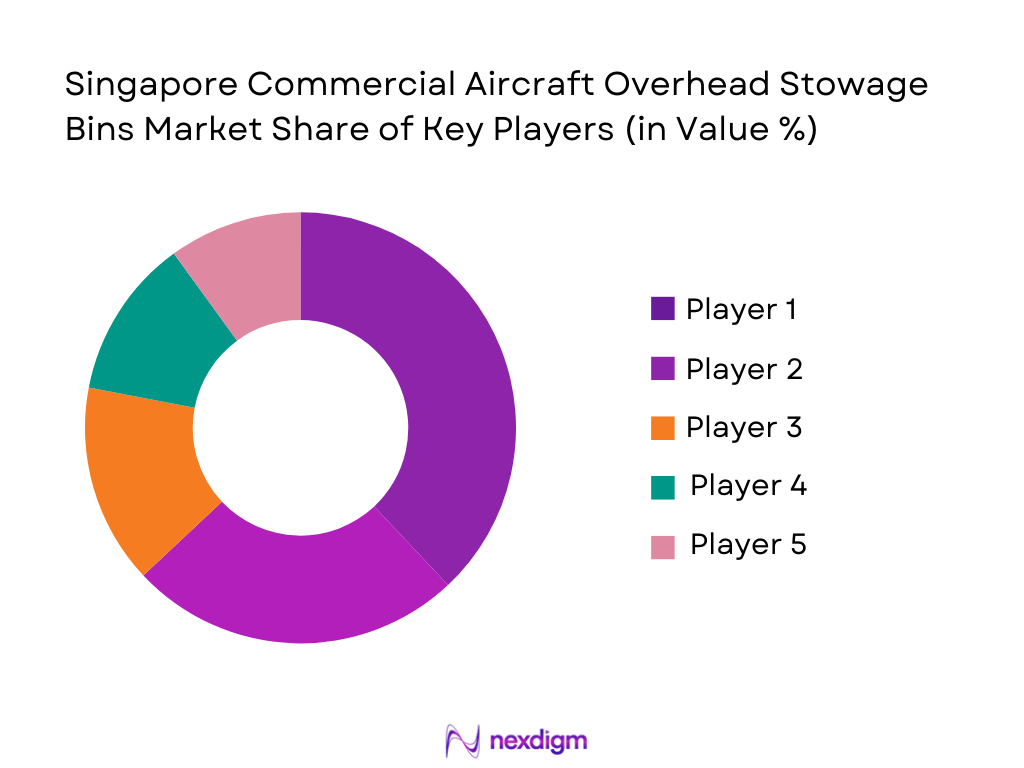

Competitive Landscape

The Singapore Commercial Aircraft Overhead Stowage Bins Market is moderately consolidated, with global cabin interior OEMs partnering closely with local MRO and integration specialists. Major players leverage long-term airline contracts, certification expertise, and regional service networks to maintain competitive positioning, while smaller suppliers focus on niche retrofit programs.

| Company Name | Establishment Year | Headquarters | Technology Focus | Market Reach | Key Products | Revenue | Regional Integration Capability |

| Safran Cabin | 1946 | France | ~ | ~ | ~ | ~ | ~ |

| Collins Aerospace | 2018 | USA | ~ | ~ | ~ | ~ | ~ |

| Diehl Aviation | 2006 | Germany | ~ | ~ | ~ | ~ | ~ |

| ST Engineering Aerospace | 1990 | Singapore | ~ | ~ | ~ | ~ | ~ |

| Jamco Corporation | 1955 | Japan | ~ | ~ | ~ | ~ | ~ |

Singapore Commercial Aircraft Overhead Stowage Bins Market Analysis

Growth Drivers

Fleet Modernization and High Aircraft Utilization in Regional Operations:

Fleet modernization and high aircraft utilization act as a primary growth driver for the Singapore Commercial Aircraft Overhead Stowage Bins Market as airlines continuously upgrade cabin interiors to maintain operational efficiency and passenger appeal. Aircraft operating from Singapore typically record high daily utilization due to dense regional route networks, accelerating cabin wear and driving frequent refurbishment cycles. Overhead stowage bins are among the most stressed cabin components, prompting regular replacement during scheduled maintenance. Airlines prioritize modern bin systems that support larger carry-on luggage and faster boarding. Leasing companies also mandate interior upgrades to protect asset value during aircraft transitions. Singapore’s strong narrow-body fleet presence amplifies this demand dynamic. Together, these factors sustain consistent procurement volumes and reinforce long-term market demand.

Operational Efficiency, Weight Reduction, and Passenger Experience Optimization:

Operational efficiency, weight reduction, and passenger experience optimization represent a critical growth driver shaping purchasing decisions. Lightweight stowage bins directly contribute to reduced aircraft operating weight, supporting fuel efficiency and emissions objectives pursued by airlines. Advanced composite materials allow weight savings without compromising strength or safety compliance. Airlines quantify lifecycle fuel savings, making lightweight bin systems economically attractive despite higher upfront costs. Larger-capacity bins also enhance passenger satisfaction by accommodating carry-on luggage more effectively, reducing gate-check delays. Singapore-based carriers emphasize cabin comfort to maintain competitive differentiation. Regulatory encouragement for efficiency improvements further reinforces adoption. Collectively, these factors drive sustained demand for advanced overhead stowage solutions across new installations and retrofits.

Market Challenges

Stringent Certification, Safety Compliance, and Regulatory Approval Processes:

Stringent certification, safety compliance, and regulatory approval processes represent a significant challenge for the Singapore Commercial Aircraft Overhead Stowage Bins Market, as every design, material, and installation method must comply with rigorous aviation safety standards. Overhead stowage bins are subject to strict fire resistance, impact tolerance, and load-bearing requirements, which increase development timelines and costs for manufacturers. Any modification to bin size, material composition, or mounting mechanism often requires recertification, limiting rapid innovation. Airlines and leasing companies tend to favor already-certified products, reducing opportunities for new entrants and alternative designs. The need for alignment between international certification bodies further complicates approval pathways. Documentation, testing, and audit requirements place additional cost burdens on suppliers. These regulatory complexities collectively slow product introduction cycles and constrain flexibility in responding to evolving airline cabin requirements.

Supply Chain Volatility and Dependence on Advanced Composite Materials:

Supply chain volatility and dependence on advanced composite materials pose ongoing challenges as overhead stowage bins increasingly rely on specialized lightweight materials. Carbon composites, thermoplastics, and hybrid materials are sourced from a limited number of qualified global suppliers, creating exposure to material shortages and price fluctuations. Disruptions in logistics or production schedules can delay delivery timelines, affecting airline maintenance and retrofit planning. Long lead times reduce supplier responsiveness during peak MRO seasons. Cost volatility complicates long-term procurement contracts with airlines and leasing companies. Inventory buffering increases working capital requirements for manufacturers and integrators. Limited local sourcing options heighten dependency risks. Together, these factors create operational uncertainty, pressure profit margins, and challenge consistent supply reliability within the Singapore aviation ecosystem.

Opportunities

Expansion of Regional Aircraft Retrofit and Cabin Modernization Programs:

Expansion of Regional Aircraft Retrofit and Cabin Modernization Programs presents a strong opportunity for the Singapore Commercial Aircraft Overhead Stowage Bins Market as airlines increasingly focus on extending the operational life of existing fleets. High aircraft utilization across Southeast Asian routes accelerates cabin wear, making stowage bin replacement a priority during scheduled maintenance checks. Singapore’s position as a regional MRO hub enables efficient execution of retrofit programs with minimal aircraft downtime. Airlines and lessors favor certified, modular bin solutions that can be installed quickly and standardized across multiple aircraft types. The presence of advanced integration facilities at Changi and Seletar supports large-scale refurbishment projects, while leasing transitions further drive demand for interior conformity upgrades. This environment creates recurring procurement opportunities for suppliers offering retrofit-optimized designs and rapid installation capabilities.

Adoption of Lightweight and Smart Cabin Interior Technologies:

Adoption of Lightweight and Smart Cabin Interior Technologies offers significant growth potential as airlines seek operational efficiency and enhanced passenger experience. Lightweight composite stowage bins contribute directly to reduced aircraft weight, supporting fuel efficiency and emissions reduction objectives. Smart bins equipped with sensors enable condition monitoring, predictive maintenance, and improved asset management, aligning with airline digitalization strategies. Singapore’s technologically advanced aviation ecosystem encourages early adoption of such innovations, supported by strong regulatory frameworks and OEM partnerships. Airlines operating premium and high-frequency routes value data-enabled interiors to optimize turnaround times and maintenance planning. As certification pathways for smart components mature, suppliers integrating digital features with proven lightweight materials are well positioned to capture emerging demand and differentiate their offerings in a competitive market.

Future Outlook

The future outlook for the Singapore Commercial Aircraft Overhead Stowage Bins Market reflects stable growth driven by continuous fleet renewal, sustained retrofit activity, and rising passenger expectations for cabin convenience. Airlines are expected to prioritize lightweight, high-capacity bin systems to support fuel efficiency and faster turnaround times. Technological progress in composite materials, modular designs, and smart monitoring features will shape product differentiation. Strong regulatory enforcement will maintain high replacement demand, while Singapore’s role as a regional aviation hub will attract integration and aftermarket projects, supporting consistent demand across narrow-body and wide-body aircraft segments over the medium term for industry stakeholders.

Major Players

- Safran Cabin

- Collins Aerospace

- Diehl Aviation

- ST Engineering Aerospace

- Jamco Corporation

- Zodiac Aerospace

- FACC

- Recaro

- Aviointeriors

- Lufthansa Technik

- Nordam

- Triumph Interiors

- GKN Aerospace

- AIM Altitude

- Aernnova

Key Target Audience

- Commercial airlines

- Aircraft leasing companies

- MRO service providers

- Cabin interior OEMs

- Aerospace component distributors

- Airport authorities

- Investments and venture capitalist firms

- Government and regulatory bodies

Research Methodology

Step 1: Identification of Key Variables

Market variables were identified through aviation procurement data, fleet statistics, and cabin retrofit activity. Demand drivers and constraints were mapped across airline, leasing, and MRO stakeholders. Regulatory and certification influences were incorporated. Data relevance was validated through cross-source comparison.

Step 2: Market Analysis and Construction

Quantitative data were compiled from civil aviation authorities, OEM disclosures, and company filings. Market structure was defined by platform and product type. Regional activity concentration was assessed. Consistency checks ensured data integrity.

Step 3: Hypothesis Validation and Expert Consultation

Preliminary findings were reviewed against industry expert insights. Assumptions were tested using operational benchmarks. Divergences were reconciled through secondary validation. Final hypotheses reflected consensus industry views.

Step 4: Research Synthesis and Final Output

All findings were synthesized into a unified framework. Redundancies were eliminated. Analytical coherence was ensured across sections. Outputs were finalized for decision-making relevance.

- Executive Summary

- Singapore Commercial Aircraft Overhead Stowage Bins Market Research Methodology

(Definitions, Scope, Industry Assumptions, Market Sizing Approach, Primary & Secondary Research Framework, Data Collection & Verification Protocol, Analytic Models & Forecast Methodology, Limitations & Research Validity Checks)

- Market Definition and Scope

- Value Chain & Stakeholder Ecosystem

- Regulatory / Certification Landscape

- Sector Dynamics Affecting Demand

- Strategic Initiatives & Infrastructure Growth

- Growth Drivers

Rising aircraft fleet modernization programs in Southeast Asia

Strong narrow-body aircraft demand supporting cabin upgrades

Weight reduction initiatives to improve fuel efficiency

Increasing passenger expectations for larger carry-on capacity

Regulatory focus on safety-certified cabin interiors - Market Challenges

High certification and compliance costs for cabin components

Supply chain dependence on specialized composite materials

Long replacement cycles in existing aircraft fleets

Customization complexity across aircraft variants

Pressure on pricing from airline cost containment strategies - Market Opportunities

Growth in retrofit programs for in-service aircraft

Adoption of lightweight and modular bin designs

Expansion of regional aviation and low-cost carriers - Trends

Integration of larger pivot bins in single-aisle aircraft

Use of advanced composites for weight optimization

Standardization of cabin interior modules

Increased focus on quick-install retrofit solutions

Digital tracking and smart cabin component adoption - Government Regulations & Defense Policy

Civil aviation authority cabin safety certification requirements

Fire resistance and impact tolerance standards for interiors

Environmental regulations encouraging lightweight materials - SWOT Analysis

Stakeholder and Ecosystem Analysis

Porter’s Five Forces Analysis

Competition Intensity and Ecosystem Mapping

- By Market Value, 2020-2025

- By Installed Units, 2020-2025

- By Average System Price, 2020-2025

- By System Complexity Tier, 2020-2025

- By System Type (In Value%)

Fixed bin systems

Pivot bin systems

Large-capacity pivot bins

Lightweight modular bins

Smart sensor-enabled bins - By Platform Type (In Value%)

Narrow-body commercial aircraft

Wide-body commercial aircraft

Regional jets

Business jets

Freighter aircraft conversions - By Fitment Type (In Value%)

Line-fit installations

Retrofit installations

Cabin reconfiguration upgrades

Life-extension retrofit programs

Aftermarket replacement fitment - By EndUser Segment (In Value%)

Full-service commercial airlines

Low-cost carriers

Charter and leasing operators

Business aviation operators

Maintenance repair and overhaul providers - By Procurement Channel (In Value%)

Direct OEM procurement

Tier-1 cabin interior suppliers

Aircraft leasing company contracts

MRO-driven procurement

Authorized aftermarket distributors - By Material / Technology (in Value %)

Advanced composite structures

Carbon fiber reinforced polymers

Lightweight aluminum alloys

Hybrid composite-metal systems

Fire-resistant thermoplastic materials

- Market structure and competitive positioning

- Market share snapshot of major players

CrossComparison Parameters (Product weight, Material technology, Certification capability, Customization flexibility, OEM partnerships, Retrofit expertise, Production scalability, Aftermarket support, Cost competitiveness, Delivery lead time) - SWOT Analysis of Key Players

- Pricing & Procurement Analysis

- Key Players

Safran Cabin

Collins Aerospace Interiors

Diehl Aviation

Zodiac Aerospace Interiors

Jamco Corporation

Recaro Aircraft Seating

FACC Cabin Systems

Aviointeriors

Nordam Group Interiors

Aernnova Cabin Interiors

ST Engineering Aerospace

Triumph Interiors

GKN Aerospace Interiors

AIM Altitude

Lufthansa Technik Cabin Solutions

- Airlines prioritize lightweight bins to reduce operating costs

- Leasing companies favor standardized bin configurations

- MRO providers focus on fast-turnaround retrofit solutions

- Business aviation operators demand premium interior finishes

- Forecast Market Value, 2026-2035

- Forecast Installed Units, 2026-2035

- Price Forecast by System Tier, 2026-2035

- Future Demand by Platform, 2026-2035