Market Overview

The USA automotive lifts market is valued at USD ~ billion, a significant segment within the automotive aftermarket and repair industries. The demand for automotive lifts in the USA is directly linked to the growing automotive fleet, which results in increasing vehicle maintenance needs across both commercial and personal sectors. These lifts enable efficient and safe vehicle servicing, making them indispensable in repair shops, dealerships, and heavy-duty workshops. Automotive lifts support diverse applications, from routine maintenance to heavy-duty vehicle servicing, driving steady demand growth in a mature market.

The USA automotive lifts market is concentrated in key regions, including the Northeast, Southeast, and West, where major automotive production facilities and repair centers are located. These areas dominate due to high vehicle population density, strong automotive production, and established service networks. Major global countries such as China and Germany also influence supply chain dynamics, providing technological innovations and cost-effective manufacturing solutions that impact pricing and service standards in the USA.

Market Segmentation

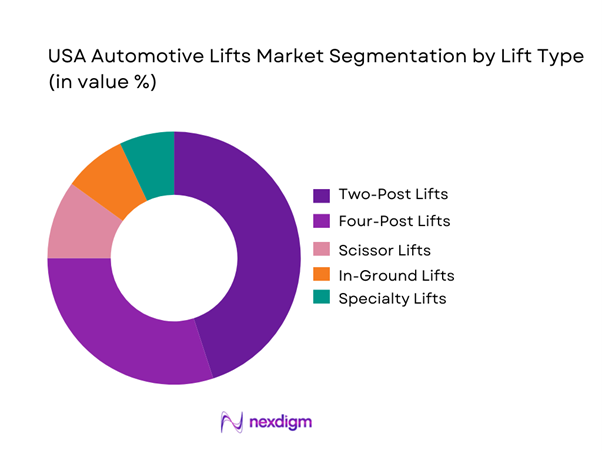

By Lift Type

The market for automotive lifts in the USA is segmented into two-post lifts, four-post lifts, scissor lifts, in-ground lifts, and specialty lifts. Among these, two-post lifts dominate the market, primarily driven by their versatility and cost-effectiveness for independent repair shops. This segment has the highest market share as these lifts are compatible with a broad range of vehicles, from passenger cars to light trucks. Their popularity is also influenced by the rising demand from smaller workshops and independent garages looking to offer efficient services at a lower installation cost.

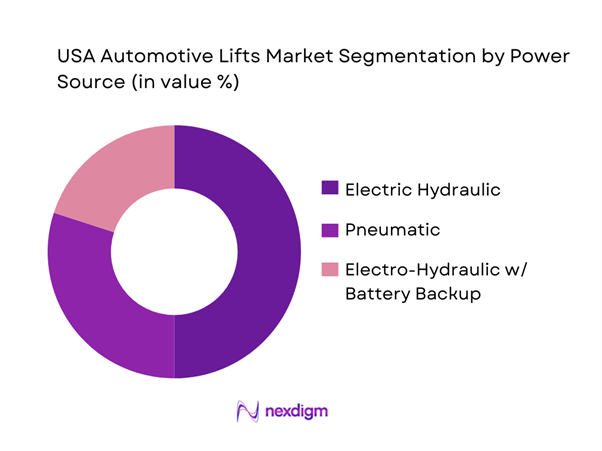

By Power Source

The power source segmentation of the USA automotive lifts market is split into electric hydraulic, pneumatic, and electro-hydraulic with battery backup systems. Among these, electric hydraulic lifts continue to dominate the market, driven by their cost-effectiveness, ease of installation, and lower operational costs compared to pneumatic systems. Electric hydraulic lifts are suitable for both light-duty and heavy-duty lifts, offering a broad range of applications across independent workshops, OEM dealers, and commercial fleet operators.

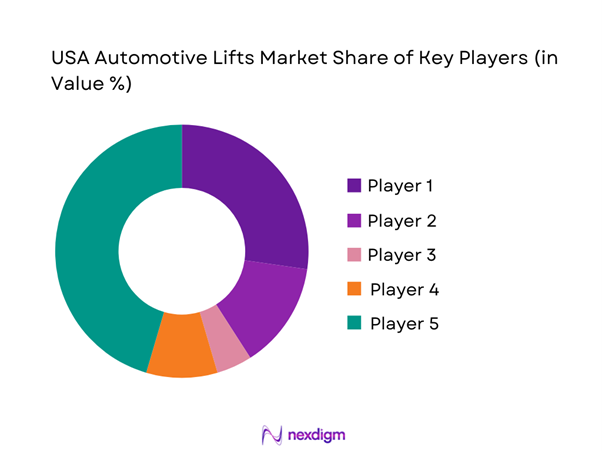

Competitive Landscape

The USA automotive lifts market is dominated by a few major players, including American Custom Lifts and global or regional brands like BendPak, Challenger Lifts, and Atlas Automotive Equipment. This consolidation highlights the significant influence of these key companies.

| Company | Year Established | Headquarters | Market Share (%) | Lift Types Offered | Service Coverage | Digital Features |

| BendPak Inc. | 1965 | California | ~ | ~ | ~ | ~ |

| Rotary Lift | 1925 | Wisconsin | ~ | ~ | ~ | ~ |

| Challenger Lifts | 1985 | Kentucky | ~ | ~ | ~ | ~ |

| Hunter Engineering Co. | 1946 | Missouri | ~ | ~ | ~ | ~ |

| Stertil-Koni USA | 1957 | Pennsylvania | ~ | ~ | ~ | ~ |

USA Automotive Lifts Market Analysis

Growth Drivers

Rising Demand for Vehicle Maintenance

The increasing number of vehicles on the road has amplified the need for regular maintenance and repair, driving a surge in demand for automotive lifts. As vehicle ownership expands and consumers seek longer-lasting, well-maintained vehicles, automotive service centers and dealerships are investing in high-quality lift systems to meet the growing demand for faster and more efficient service. With advanced lifts, repair shops can handle a wider variety of tasks, including inspections, upgrades, and specialized repairs, which increases the overall service volume. This continuous need for vehicle upkeep supports market growth in both the commercial and residential sectors.

Expansion of Automotive Repair Services

The automotive repair services market is expanding rapidly, fueled by an increase in small businesses, franchises, and independent repair shops. This growing industry requires a wide range of lifting equipment capable of supporting diverse vehicle types, from compact cars to heavy-duty trucks. The demand for flexible and reliable automotive lifts has risen alongside the expansion of these businesses, especially in urban and suburban areas. As the automotive repair sector grows, so does the need for modern, efficient lifts that can handle a variety of maintenance and repair tasks, further stimulating demand for high-quality lift systems.

Challenges

High Initial Investment

A major barrier to the growth of the automotive lifts market is the high initial investment required for purchasing and installing quality lifting equipment. Premium models, such as 4-post and in-ground lifts, come with substantial upfront costs, which can be a significant challenge for smaller repair shops or new businesses. These costs, along with installation and maintenance expenses, can make it difficult for some companies, particularly in emerging markets or with limited budgets, to access these essential tools. This financial hurdle often limits the adoption of advanced lifts, slowing down market penetration in certain sectors.

Limited Skilled Workforce

There is a growing shortage of skilled technicians trained to operate, install, and maintain advanced automotive lifts. As lift systems become more sophisticated and feature-rich, the expertise required to manage these systems becomes more specialized. The gap between the demand for trained technicians and the available workforce is widening, creating significant operational challenges. Without the necessary skills, service quality can be compromised, leading to potential delays and increased repair costs. This shortage of skilled labor also hampers the growth of the market, as businesses may struggle to find or retain qualified staff to keep their lifts functioning at peak performance.

Opportunities

Shift Toward Electrification

The rise of electric vehicles (EVs) presents a significant growth opportunity for the automotive lifts market. Unlike traditional vehicles, EVs have unique servicing requirements, including different lifting specifications due to their battery weight distribution and vehicle design. As EV adoption increases, automotive repair centers will require lifts that are specifically designed to safely and efficiently handle these vehicles. This shift toward electrification is creating a new niche within the automotive lifts market, with manufacturers focusing on developing advanced lifting solutions tailored to EVs, thus opening up a valuable segment for growth in the coming years.

Automotive Industry Growth in Emerging Markets

As automotive production and vehicle ownership soar in emerging markets, there is a growing demand for advanced automotive repair solutions, including high-quality lifts. Many repair shops and service providers in these regions are looking to the USA for state-of-the-art lift technologies and systems. This growing interest presents an opportunity for American lift manufacturers to expand their reach globally through exports. As automotive infrastructure continues to develop in emerging economies, the demand for efficient and reliable automotive lifts will rise, offering manufacturers the chance to grow their market share by catering to new international markets.

Future Outlook

The future of the USA automotive lifts market looks promising as demand continues to grow with the expansion of the automotive sector. Technological advancements, such as increased automation in automotive repair shops, will provide further growth opportunities. Market players are expected to focus on product innovation to address new challenges presented by vehicle electrification and increasingly stringent environmental regulations.

Major Players

- American Custom Lifts

- BendPak

- Challenger Lifts

- Atlas Automotive Equipment

- Tufton Lifts

- SI Automotive Equipment

- Autolift

- Shinn Fu Company

- Fluid Power Equipment

- Motorcycle Lifts USA

- Scissor Lift Systems

- Dayton Lifts

- Heavy Duty Lifts

- Champion Lifts

- Ranger Products

Key Target Audience

- Investments and venture capitalist firms

- Government and regulatory bodies (USA)

- Automotive repair workshops

- Vehicle manufacturers

- Fleet management companies

- Car dealerships

- E-commerce platforms and distributors

- Garage equipment suppliers

Research Methodology

Step 1: Identification of Key Variables

The identification of key variables involves understanding the drivers, challenges, and trends affecting the automotive lifts market. This includes vehicle production rates, repair and maintenance trends, and consumer preferences for lift types and functionalities.

Step 2: Market Analysis and Construction

Market analysis is conducted by aggregating data from primary and secondary sources, utilizing both qualitative and quantitative methods to ensure a comprehensive market construction. This involves trend identification, market sizing, and competitive analysis.

Step 3: Hypothesis Validation and Expert Consultation

The hypotheses formed from initial research are validated through expert consultations, including interviews with industry professionals and analysis of competitor strategies. This helps refine market projections and identify key trends.

Step 4: Research Synthesis and Final Output

The final report synthesizes insights from the previous steps, ensuring a cohesive and clear understanding of the market dynamics. The final output is validated and presented for client use, ready for strategic decision-making.

- Executive Summary

- Research Methodology (Market Definitions and Inclusions/Exclusions, Abbreviations, Topic-Specific Taxonomy, Market Sizing Framework, Revenue Attribution Logic Across Use Cases or Care Settings, Primary Interview Program Design, Data Triangulation and Validation, Limitations and Data Gaps)

- Definition and Scope

- Market Genesis and Evolution

- Automotive Lifts Usage / Value-Chain / Care-Continuum Mapping

- Business Cycle and Demand Seasonality

- USA Industry / Service / Delivery Architecture

- Growth Drivers

Rising Demand for Vehicle Maintenance

Expansion of Automotive Repair Services

Technological Advancements in Lift Systems

Growing Automotive Production

Increasing Vehicle Fleets - Challenges

High Initial Investment

Limited Skilled Workforce

Complex Regulatory Requirements

High Maintenance Costs

Demand Fluctuations in Off-Season - Opportunities

Shift Toward Electrification

Automotive Industry Growth in Emerging Markets

Rising Adoption of Automation in Vehicle Maintenance

Growth in E-Commerce and Distribution Channels

Renewed Interest in Car Restoration - Regulatory & Policy Landscape

- SWOT Analysis

- Stakeholder & Ecosystem Analysis

- Porter’s Five Forces Analysis

- Competitive Intensity & Ecosystem Mapping

- By Market Value, 2019–2024

- By Unit Shipment, 2019–2024

- By Average Selling Price (ASP) Trends, 2019–2024

- By Technology / Product / Platform Type (in Value %)

Hydraulic Lifts

Electric Lifts

Pneumatic Lifts

Mechanic Lifts

Manual Lifts - By Deployment / Delivery / Distribution Model (in Value %)

Direct Sales

Distributors

Online Retail

Aftermarket Service

- By End-Use Industry / Customer Type (in Value %)

Automotive Workshops

Car Dealerships

Garage Equipment Suppliers

Mobile Service Providers

Industrial & Commercial

- By Region (in Value %)

Northeast

Southeast

Midwest

West

Southwest

- Competition ecosystem overview

- Cross Comparison Parameters (Technology, Product Type, Price, Aftermarket Service, Brand Recognition, Distribution Channels, Product Innovation, Regional Presence)

- SWOT analysis of major players

- Pricing and commercial model benchmarking

- Detailed Profiles of Major Companies

American Custom Lifts

BendPak

Challenger Lifts

Atlas Automotive Equipment

Tufton Lifts

SI Automotive Equipment

Autolift

Shinn Fu Company

Fluid Power Equipment

Motorcycle Lifts USA

Scissor Lift Systems

Dayton Lifts

Heavy Duty Lifts

Champion Lifts

Ranger Products

- Buyer personas and decision-making units

- Procurement and contracting workflows

- KPIs used for evaluation

- Pain points and adoption barriers

- By Market Value, 2025–2030

- By Unit Shipment, 2025–2030

- By Average Selling Price (ASP) Trends, 2025–2030